SCRANTON, Pa. (May 21, 2012) -- Like many Army installations, Scranton Army Ammunition Plant, Pa., has a recycling program to minimize material disposal. Unlike most other Army installations, at SCAAP, the materials diverted include projectile casings, steel, mixed metals, scrap wood, wood pallets, lead-acid batteries, equipment, chemicals, cardboard, paper products and electronics. In addition, it uses closed loop and filtration systems to reduce total waste streams and support pollution prevention goals.

The plant produces large caliber ammunition casings that require a coating. Application of this coating can impact air quality within the plant and increase release of volatile organic compounds outside. Reducing the amount of paint and solvent required was one goal that technology could help achieve.

SCAAP procured and installed electrostatic atomizing paint guns, which improved efficiency in the coating process, reduced material waste and improved overall air quality while reducing the facility volatile organic compound emissions by 60 percent.

The plant also sought to reduce zinc phosphate in its production process to minimize discharge into sewage and waterways that lead to the Chesapeake Bay. Steel ammunition parts must be treated prior to painting to improve corrosion resistance and paint adherence. That treatment results in a zinc phosphate waste stream that requires treatment before release into the municipal sewer.

SCAAP initiated a research, development, test and evaluation initiative to evaluate alternative chemicals for replacement of the alkaline bath and zinc phosphate treatment. It is also evaluating chemicals in hopes of finding one that would not require treatment prior to discharge, allowing the plant to conserve energy and save costs.

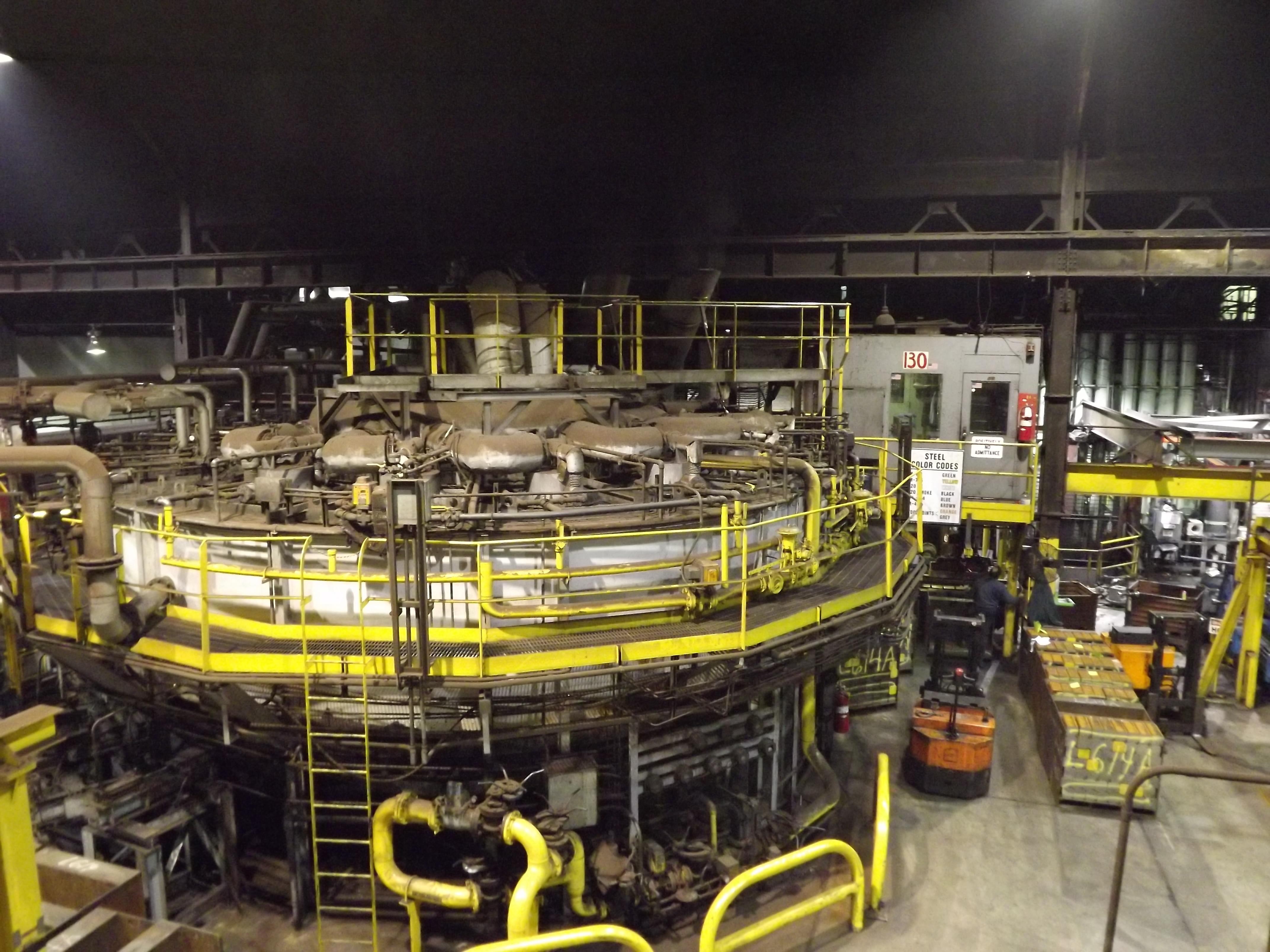

A number of other efforts have been put in place to promote energy conservation and efficiency. Modernization of one of the rotary hearth furnaces is expected to yield a 25 percent reduction in natural gas consumption per year and will help reduce greenhouse gases.

The forge press line modernization reduces horsepower, which lowers the electrical intensity and is expected to yield a 15 percent reduction in the press line's electricity consumption. Replacing the 50-year-old Keeler boilers with more efficient boilers is expected to lower natural gas consumption by 20 percent and emissions by 30 percent, supporting goals for greenhouse gases, fuel use and energy consumption reduction.

A rainwater capture system on the roof collected 2 million gallons in a single year for use as cooling water in production operations. This effort reduces the demand for city water, lessens the storm-water discharge and helps lower operational costs.

A membrane ultra-filtration system recycles all wastewater from the forging operation and reuses it in the plant's noncontact cooling water system. This system also allows SCAAP to eliminate a point of discharge to the Scranton sewer system and the associated permit. The system has recycled more than 1 million gallons of oily wastewater from the forging operation.

SCAAP's operating contractor continually works to evaluate environmental aspects and impacts of its industrial mission. SCAAP's International Standards Organization-certified environmental management system ensures success in meeting its environmental goals and helps keep the plant in compliance with all requirements.

"The team strives to incorporate energy efficiency, environmental friendliness and cost savings into every modernization effort undertaken at the installation," said Richard P. Hansen, SCAAP commander's representative. "We are honored and humbled to have been chosen to receive this award."

The technology and best practices SCAAP implemented -- reducing and reusing water, improving air emissions in the production facility, reducing hazardous materials by evaluating the latest technology and engaging in multiple energy efficiency projects -- contributed to its sustainability success.

Related Links:

Assistant Secretary of the Army for Installations, Energy & Environment

Social Sharing