WATERVLIET ARSENAL, N.Y. (March 29, 2012) -- Imagine the stress involved in having a job where a simple, stubby-pencil error in a calculation may mean that your business will lose out on a multimillion dollar order. Or worse yet, your calculation may have helped your company get the order but then you find out that the manufacturing costs to support the order may cost your company hundreds of thousands of dollars.

Why would anyone want that job? Some people do, and the Watervliet Arsenal is fortunate that they have stepped up into the world of production planning. Some have said this is the most detailed job at the Arsenal, which says a lot considering that Arsenal machinists work in a world of thousandths-of-an-inch measured cuts.

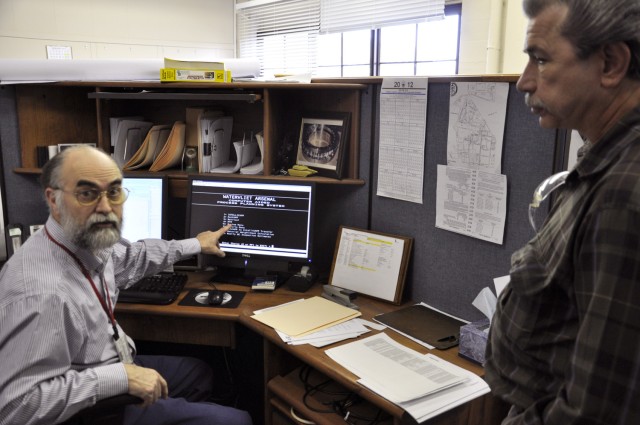

In a rarely visited area, in a building that was built right after World War I, a small team of 10 planners develop the production plan for every order that comes into the Arsenal. In fiscal year 2011 these planners worked on hundreds of orders that were valued at nearly $100 million.

"Our work begins when the request for a quote comes to the Arsenal for a specific product, such as for a 120mm cannon for an Abrams Tank, and it continues throughout the lifecycle of the manufactured product," said Mike Dumas, supervisor of production planning at the Arsenal. "In essence, we track a product from its concept to its grave."

The production planners are not the folks who come to the Arsenal right after school. The Arsenal's 10 planners have more than 200,000 hours of experience in just about all phases of production, from forge operations to tool design.

They are skilled artisans who not only know the Arsenal's capabilities and capacity very well, they also know such detailed information as to how much time it takes to make each cut on a tube. This high level experience and depth of knowledge directly affects whether or not the Arsenal obtains a profit or a loss, both of which are not desirable actions.

As an Army-owned-and-operated manufacturing facility, the Arsenal has a very thin margin of error in its revenue generated from sales. The Arsenal works on a cost-reimbursable basis, which means that it cannot plan for a profit nor have a loss from a product line. For example, if there are any cost savings realized during the production cycle, the savings are returned to the customer, who in the end is the American taxpayer. If there is a loss, the Arsenal cannot turn to the customer and say you owe more. That is why each calculation performed during the request for quote process is painstakingly verified over and over again.

Surprisingly, in the era of high technology it isn't high tech that provides the launch point for these planners when calculating a quote or the production plan for an order. It is files, old files.

Just outside the bowels of the production planning office is a room solely dedicated to storing files, thousands of them.

Tom Ruchlicki, a long-time production planner, said that each file tells the complete history of every product manufactured at the Arsenal, from a firing pin to an Abrams Tank cannon, since the early 1970s.

"Our files go back to the Vietnam War," Ruchlicki said. "And in each file, there are documents that explain the quote process, the tools required, the production schedule, the speed of machines, down to the length of each cut made on a piece of steel to manufacture that product."

Dumas added that one of the best by-products coming out of these files is the history of what went right or wrong during the production cycle. In essence, what the Army calls an after-action review.

"When we get a request for a quote, we turn to these files to see if we have manufactured that product line before or maybe a similar product line," Dumas said. "Then as we build the quote, we factor in the lessons learned from the previous order to ensure we hit the target between a profit or a loss."

The lessons learned speak about such things as to whether or not a specialized heat treatment worked down to did the Arsenal use the right angles of cuts on the product to what processes and procedures were not required that resulted in reduced manufacturing time.

Such is the life of being a production planner at an Army-owned-and-operated manufacturing center. Razor thin margins of error managed by just a handful of folks who have the most detailed job at the Watervliet Arsenal.

Why would anyone want this job? Some do, and the taxpayers can feel lucky that they do.

The Watervliet Arsenal (pronounced water-vleet") is an Army-owned-and-operated manufacturing facility located in Watervliet, New York. The Arsenal is the oldest, continuously active arsenal in the United States, having begun operations during the War of 1812.

Today's Arsenal is relied upon by U.S. and foreign militaries to produce the most advanced, high tech, high powered weaponry for cannon, howitzer, and mortar systems. This National Historic Registered Landmark has an annual economic benefit to the local community in excess of $100 million.

Related Links:

Army.mil: Science and Technology News

Social Sharing