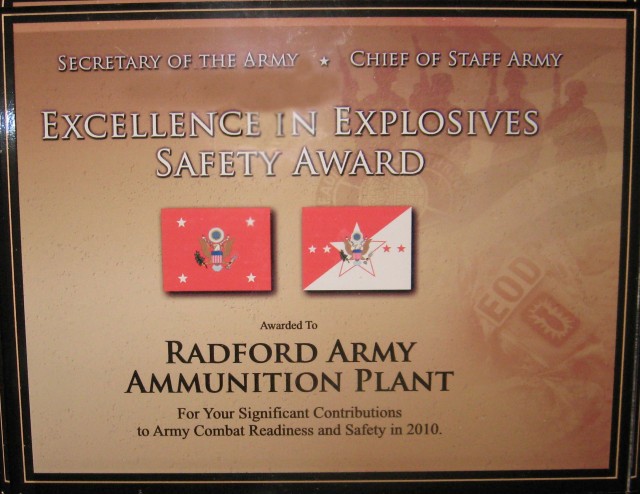

RADFORD, Va.-Radford Army Ammunition Plant employees recently received the prestigious Army Excellence in Explosive Safety Award for fiscal year 2010 from Brig. Gen. Gustave F. Perna, commanding general of the Joint Munitions Command.

Ken Mahoney, risk manager at RFAAP, and Joe Betteken, senior safety manager of Alliant TechSystems, Inc., operations contractor, accepted the award on behalf of all employees at RFAAP.

Officials at RFAAP report that this award reflects the safety culture at Radford which emphasizes that each and every employee is a safety officer and is responsible for the safety and well-being of the facility. To further support this culture, the entire government staff is certified in risk management.

One of the main points of Perna's visit to Radford was a focus on safety.

"As an end state at JMC's installations, I visualize a trained and ready workforce working in a modernized environment which will improve safety, quality of life and production capability while increasing effectiveness and efficiencies. Radford is doing well," Perna said.

Essentially, Radford provides the building block material for nearly all munitions within the Department of Defense. RFAAP produces nitro-cellulose, 200 different varieties of propellants, 25 mm and 30 mm munitions, hand grenades and artillery simulators.

Radford received the safety award in recognition of its exemplary safety efforts.

For example, in FY 2010, RFAAP had a total recordable injury rate of 1.9 versus an industry standard of 3.2 for chemical and explosive industrial facilities.

Also in 2010, RFAAP worked to eliminate the use of perchlorates in the production of hand grenade and artillery simulators, which helps eliminate environmental risks and decreases potential hazards to warfighters.

In response to a rise in ergonomic injuries, in FY 2010, RFAAP established a unique daily flex and stretch program, expected to help reduce workers' ergonomic injuries.

As a result of RFAAP's continued dedication to improving safety procedures and eliminating foreign debris in production, FY 2010 showed a result of an all time low in flash fires of 2.2 flash fires for one million pounds of propellant produced.

RFAAP continues to build and sustain a notable Army explosive and chemical production safety program that protects the workforce, infrastructure and environment.

Social Sharing