CAMP LIBERTY, Iraq - Keeping mission-essential equipment operational can be difficult when Soldiers come to a new dusty environment with less-than-perfect road conditions. It is ever harder when you have never seen the equipment before.

Soldiers in the 1st Cavalry Division Special Troops Battalion motor pool have been able to do exactly that during their tour here.

"You won't find this in the schoolhouse," said Brooklyn, N.Y. native, Staff Sgt. John Daley, noncommissioned-officer-in-charge of the motor pool, generator section with Headquarters Support Company, DSTB.

First-time deployers, especially those Soldiers just out of Advanced Individual Training, have never seen an up-armored humvee before because they are theater provided equipment, he added.

"When we first got here, it was taking (the mechanics) three days to replace one humvee engine. Now, it takes them less than two," said Stockton, Calif., native, Sgt. 1st Class Elemenia Malone, battalion motor sergeant, HSC.

"The major difference between the humvees here and those that we work on (in the U.S.), is that these are more cramped with all of the extra equipment," said Braidwood, Ill. native, Spc. Phillip Corbin, floor mechanic, HSC.

Improvisation to make the equipment better started early in the deployment.

Soldiers also started welding chains to humvee doors to enable them to lock the vehicles more securely. Soldiers on quick reaction force teams can leave their vehicles ready to go without having to worry about somebody stealing their equipment out of them, added Corbin.

But Soldiers don't always have the damaged vehicles delivered to them. Sometimes they have to go out and retrieve them. One of their three tow trucks is up-armored to be able to tow vehicles damaged while on a mission in Baghdad.

Corbin, who is one of three wrecker operators at the motor pool, went outside the wire once to help tow a damaged vehicle.

"When I went out, the vehicle, which had rolled over, couldn't be pulled by another humvee," he said. "With the tow truck, a much stronger vehicle, we were able to drag it back here."

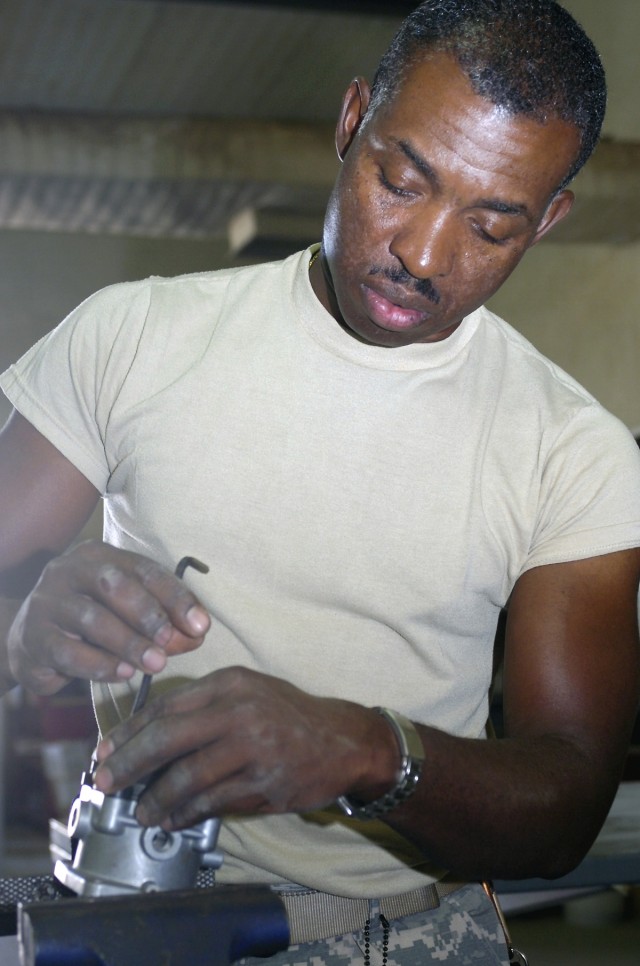

Another important group of Soldiers housed in the motor pool is the generator section. These Soldiers maintain the humvee air conditioners as well as the generators that are constantly running to supply tactical power to the First Team.

Due to the extra heat and equipment, humvees without working air-conditioners are dead-lined or not considered mission capable.

Because of mission necessity, tactical buildings here never experience power outages. The generators are always running, and must have more frequent checkups. Soldiers perform maintenance checks on the generators every 10 days as a result of this constant usage and the harsh environment, Daley said.

"Because of the dust, we burn through more coolant, oil, and air filters," he added.

The constant upkeep allows the DSTB to continue on with their mission.

"We try to catch problems before they happen," Daley said.

Social Sharing