PICATINNY ARSENAL, N.J. -- When the space shuttles roared off their launch pads to perform various missions in space that ultimately proved successful, Michael DeNude could take a measure of satisfaction.

However, DeNude doesn't work at any NASA control facilities. Typically, he can be found ambling down the various walkways of the cavernous L3 Communications Space & Navigation Division building in Budd Lake, southwest of Picatinny Arsenal.

Yet DeNude doesn't work for L3 either.

Rather, he is part of a team of six employees assigned to the L3 complex by the Defense Contract Management Agency (DCMA), a crucial component of the Department of Defense (DoD) that performs a wide range of functions within the contracting, engineering, pricing, and quality-assurance disciplines.

"Senior Department of Defense officials understand that there is a tremendous amount of work that takes place between contract award and contract closeout," said Col. Kevin P. Stoddard, Commander of DCMA Springfield.

"This is DCMA's realm, and DCMA's highly skilled, trained, certified, multi-functional workforce provides a vast array of contract administration services," he added.

DCMA services include program integration, quality assurance, engineering, earned value management, production surveillance, transportation, and property management, thereby supporting DoD, NASA, and other federal agencies.

By virtue of its broad duties and expertise before and after a contract award, DCMA contributes to the military readiness of the United States and its allies.

DCMA is a worldwide agency with about 10,660 civilian employees. The local Contract Management Office, DCMA Springfield, is headquartered at Picatinny Arsenal and operates throughout the 12 northern counties in New Jersey. The local office is also DCMA's Lead Platform Command for Munitions.

DCMA Springfield manages an average of 700 government contractors with about 5,300 active contracts.

"Although we administer hundreds of contractors having a variety of products, we must know each contractor, their processes, and the risk associated with their production," Stoddard said.

"It is not good enough to just report on the status of a contractor's operations. We expect our folks to be insightful and predictive, knowing the details that will ensure a positive outcome."

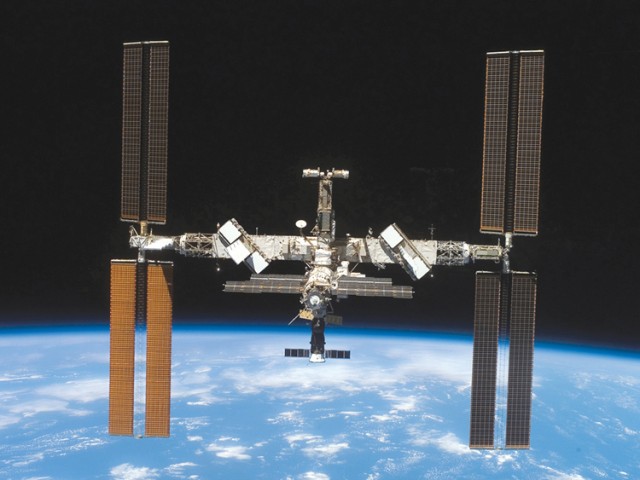

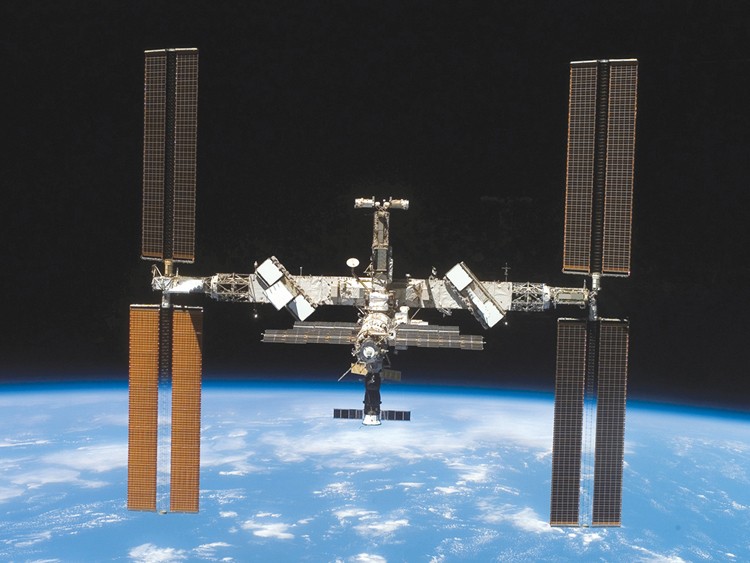

The range of contract items under oversight by DCMA are broad, ranging from basic nuts and bolts, uniforms and insignias, to sophisticated electronic systems and control-movement gyroscopes for the Hubble Space Telescope and the International Space Station.

"We literally touch pretty much everything in some way, shape or form," said John Policastro, Springfield's contracts group chief.

"In the M2 machines guns, we've got the guys who make the little firing pins, and if they don't make them right the guns don't work. So little things that seem insignificant to you and me-they are critical."

Raymond Pietruszki, the DCMA Springfield deputy director, said the agency culture reflects the idea that all government purchases are important to monitor, even items that might seem relatively mundane.

"One thing that's always been driven home is that it doesn't matter whether it's the simplest of washers or screws, munitions or weapons, an Apache helicopter, or the NASA space program" he said.

"If that warfighter needs that washer with a certain specification, he needs it for a good reason, and we have to make sure that we get it to him. Otherwise, he's in trouble, the mission is going to fail and that's unacceptable."

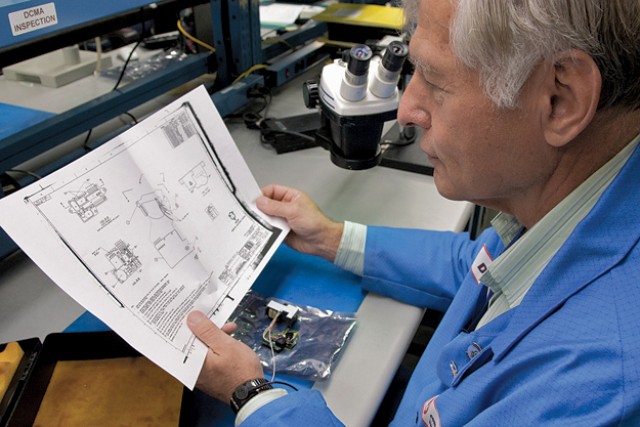

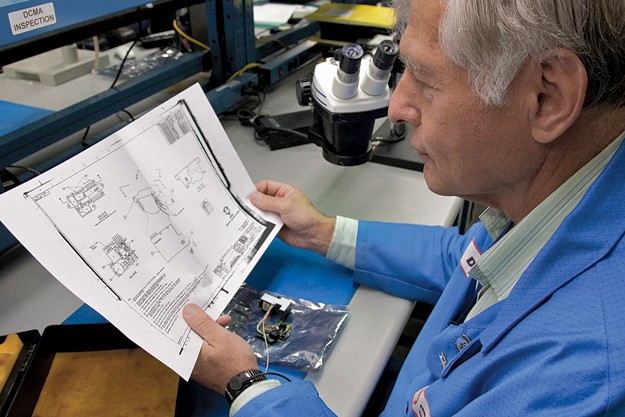

For DeNude, a senior quality assurance specialist for DCMA at L3 Communications, there is also a sense of professional accomplishment when he realizes what a quality product means to the end user.

When DeNude sees the spectacular images of the universe captured by the Hubble Space Telescope, the role that he and his team played is not overlooked.

"DCMA did the test review, inspection, certification, and acceptance of the Hubble gyros," he said. "There is a lot of pride knowing that you participated in those things."

Because DCMA is a joint military services organization, it provides contract oversight for programs for the Army, Navy, Air Force, and other military or federal government components.

For example, ITT Corp. in New Jersey provides electronic countermeasure systems for various aircraft platforms as well as detection systems for enemy radars and missiles.

L3, located at the International Trade Center at Budd Lake, provides the Army with a subsystem that gives the Paladin howitzer accurate vehicle position, gun azimuth and elevation data.

The company also provides a Position and Navigation Unit (PNU) for the Multiple Launch Rocket System.

Another product is the Improved Position and Azimuth Determining System (IPADS) for the Army, Marine Corps and National Guard. It provides precise position, elevation and direction for cannon, rocket and missile units.

Some defense contractors have enough varied and continuous contracts that it makes sense to have "resident" DCMA teams that essentially work in the production facilities. They include quality assurance, industrial specialists, earned value management specialists, engineers, contract administrators, and procurement technicians.

"They are the eyes and ears to make sure the items are made the right way," said Pietruszki. "Many of the high tech programs that we manage require our employees to have specialized training and certifications.

"Likewise, many of the sophisticated corporate cost monitoring and earned value management systems require a high level of DCMA employee competency and expertise to ensure that the government receives best value."

Added Stoddard: "We place emphasis on being ready and flexible to respond to the evolving requirements."

To have proper contract oversight, the DCMA must have employees with a broad spectrum of training and experience.

"We have production and manufacturing specialists to make sure that program performance and schedules are being met," Stoddard said. "We also have engineers who provide technical assistance."

According to DeNude, who has almost 33 years with DCMA, the relationship between contractors and quality assurance representatives is generally good.

"I've had contractors who have disagreed with what I've said," DeNude noted. "You go back and look at your specs and use that as the document from which you speak from.

"They may not like that, and don't feel they have to go to a particular degree, but the requirement is how they have to perform. You don't let it become personal. They'll always respect you for that.

"In many ways you develop a thick skin and don't take things personally if they disagree with you."

Leo Petuchovas, who is approaching 30 years with DCMA, said contractors know that contract language gives government representatives the right to perform routine inspections, so they don't chafe at the thought of having the oversight.

"They know what we have to look at," he said, noting that an organization like NASA has many mandatory inspections. "Treat them fair and they will treat you fair."

In some instances, quality assurance representatives don't work full-time at a contractor facility, according to Pam Gould the DCMA Springfield quality assurance group manager.

Instead, they are "itinerants" who perform periodic visits to contractor sites. "They have a route with maybe 8 or 12 contractors assigned to them," said Gould.

"They may spend two hours or a whole day based on how comfortable they are with the contractor's ability to perform. As new contractors come on board, there is typically more oversight."

Stoddard said various elements help determine how DCMA manages a contract.

For example, oversight considerations include the complexity of the program, critical performance characteristics, how new the contractors are to the program, along with their past performance.

How closely contracts are managed is in large part determined by the level of risk involved.

For example, a standard Army combat uniform is less risky than a combat uniform that is supposed to be fire-resistant.

Therefore, close examination, by quality assurance personnel with specialized certification, is given to the production and inspection of a fire-resistant uniform that, if faulty, could result in serious injury or death.

"When we say it must work every time because it's a surveillance radar or something that critical," Stoddard said, "we still go through those methodical checks-the hundredth time just like the first time.

"DCMA must remain vigilant."

Social Sharing