There are plenty of gems to be found at Letterkenny Munitions Center, Chambersburg, Pa. Not ordinary gems like diamonds, rubies, or emeralds. The jewels in Letterkenny's crown come in the form of dedicated employees, unique maintenance, testing and repair facilities, extensive demilitarization operations, comprehensive outloading capabilities, and vast storage facilities.

Letterkenny Munitions Center is part of the Army Joint Munitions Command's nationwide network of facilities where conventional ammunition is produced and stored.

LEMC is a tenant of Letterkenny Army Depot and sits on 16,000 acres encompassing 902 storage igloos, 10 magazines, 20 supply warehouses, 16 maintenance and operations buildings, munitions sheds and administration buildings.

Dedicated Employees

In addition to these tangible assets are LEMC's dedicated employees. Ralph Peters, logistics management specialist, has worked at LEMC for almost 40 years. Peters has seen it all, but was genuinely impressed by fellow employees in 2003 at the beginning of Operation Iraqi Freedom.

"A huge amount of ammunition was requested from storage at LEMC to be shipped overseas," said Peters. "About two-thirds of LEMC's employees responded to help load ammo into containers. People from all departments labored outside in the winter, many times in snow and into the night."

"No one grumbled," said Peters. "Even the grumblers weren't grumbling. Everyone pitched in." The common goal resulted in an uncommon bonding among employees.

Recently, Herbert Bailey, supervisor of Air Force missile shops, and Ferman Crouse, painter, pointed out the painting and stenciling on a missile container.

"Most of our maintenance painting or re-painting jobs are better than the manufacturer's original painting," commented Bailey.

"It's good, but we can do better," said Crouse.

Later, Bailey stressed, "That's the kind of great employees we have here."

LEMC supervisors recognize and utilize the skill and experience of their workforce. For example, on-site technicians assist maintenance employees with necessary drawings for repair of missiles. The knowledgeable technicians can provide faster turn-around solutions to problems at a fraction of the cost of hiring a contractor.

Maintenance, Testing and Repair

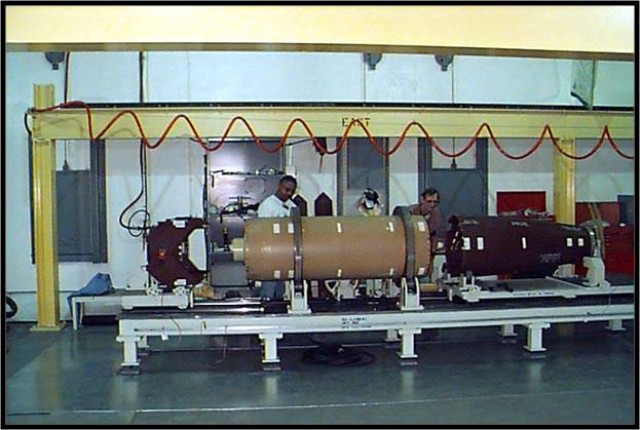

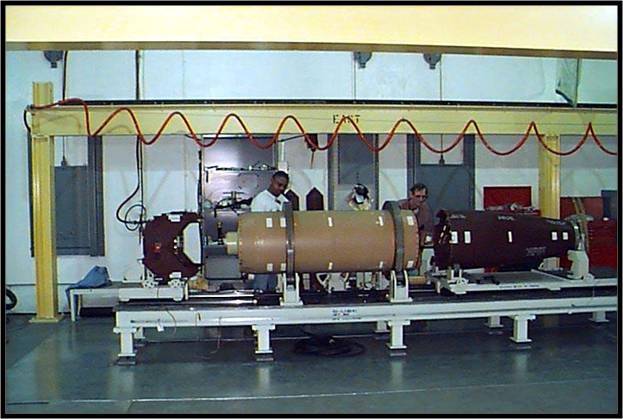

The maintenance, testing and repair facilities comprise another gem at LEMC. The maintenance staff tests 100 percent of all missiles arriving at and departing from the installation.

Two of the missile systems which LEMC maintains are the Army Tactical Missile System, or ATACMS, and the Guided Multiple Launch Rocket System, or GMLRS. LEMC is an Army depot for ATACMS and GMLRS. At LEMC, these missiles are recertified, maintained, repaired, modified, stored and demilitarized.

The ATACMS is a surface-to-surface missile. The Block I version holds 950 bomblets and has a range of 128 kilometers. The Block IA missile contains 275 bomblets which makes it lighter and increases its range to 300 kilometers.

With so many bomblets to each missile, there are times when not all bomblets explode on impact. This has become a hazard to warfighters and citizens in theater. To eliminate this problem, approximately 400 Block I and IA missiles will be refitted to a solid, unitary warhead at LEMC in its Shelf Life Extension Program. LEMC will also download and demil Block I warheads.

About 700 ATACMS are being returned to LEMC from Germany and Korea for storage. First shipments were received in June 2008.

The GMLRS is considered the Special Operations' "70 kilometer sniper rifle." GMLRS has a range of 85 kilometers, which, along with GPS precision, provides greater safety for warfighters. Approximately half of all GMLRS produced are to be stored at LEMC.

Kenneth Weikel, chief of Maintenance Division at LEMC said, "At LEMC, all missiles are tested for safety and functionality when they arrive and before they are shipped out. And all missiles stored at LEMC are tested on a periodic schedule."

Weikel continued, "Missiles that have been dropped or damaged by weather in shipping, storage or in theater are sent here for testing and repair, disassembled for reuse of parts or for recycling, or demilitarized."

To definitively diagnose a problem with an ATACMS or GMLRS missile, a maintenance employee attaches it to a special $2.5 million computer, of which LEMC has four. The diagnostic computer "talks" via satellite to the missile's computer to pinpoint the exact problem needing repair.

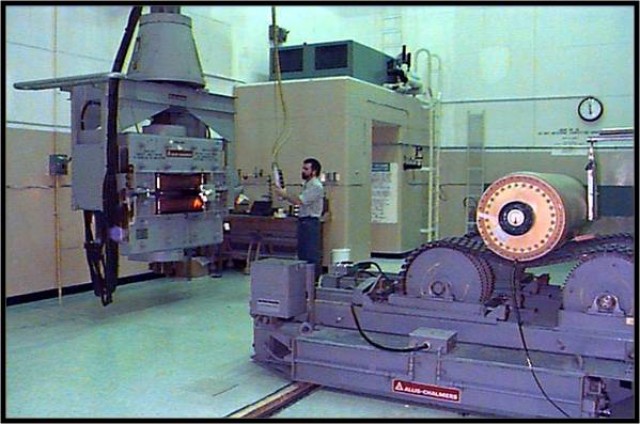

Another diagnostic gem at LEMC is its X-ray facility.

Thomas Sherman, quality assurance specialist, X-ray, said, "It was built and equipped in 1972 and the equipment lasted so long because we took such good care of it. In 2010, the outdated equipment was replaced with state-of-the-art digital equipment."

In one large, pristine bay, huge overhead X-ray machines are suspended by crane. This X-ray equipment can detect manufacturer defects, and damage from dropping, and can examine welds to determine the viability of a missile.

Another unique part of LEMC's maintenance, testing and repair capabilities is its Missile Common Test Device repair mission. An MCTD is a "computerized testing device in a suitcase." LEMC supports three-man mobile teams that use the MCTDs in the field to test ATACMS and GMLRS missiles. Nonfunctioning MCTDs are returned for repair to LEMC.

This mission now includes support to Foreign Military Sales (FMS) customers for these systems. Recently, LEMC began repairing GMLRS for the United Kingdom, and has sent teams to Greece and Turkey. There are currently a dozen more countries looking to LEMC for future support.

In addition, LEMC is the primary depot for Air Force Sidewinder, Sparrow, High Speed Anti-Radiation Missile (HARM), Joint Air to Surface Standoff Missile (JASSM), and Advanced Medium-Range Air-to-Air Missile (AMRAAM); and the primary depot for Navy HARM, Advanced Anti-Radiation Guided Missile (AARGM), and Penguin missiles.

LEMC performs full electronic testing as well as some repair, and maintenance, repair, disassembly, and full integration services for these systems. LEMC has provided these services to the Air Force since 1961 and to the Navy since 1992.

Demilitarization

LEMC's demilitarization operations are another gem in its crown. Employees at LEMC carry out several types of demil.

A Lean Six Sigma Greenbelt project established a recycling process which has become a demil model for other installations. Employees dismantle unusable missiles and recycle the scrap metal. More than $784,000 has been generated from this process which benefits the environment and saves taxpayers money.

Another demil operation at LEMC entails explosives recovery from unitary warhead missiles. The initial workload comprised about 25 Sparrow warheads per day and in fiscal year 2011 the workload is expected to employ four people. LEMC resells the recovered energetic material, or propellant, for reinvestment.

Demil operations at LEMC also include the Advanced Medium-Range Air-to-Air Missile (AMRAAM) and Sidewinder missile reclamation programs. These missiles are disassembled and parts are used for repair of viable missiles or for new production. The nose cones of unusable AMRAAM missiles especially are in demand. What was considered to be a lifetime supply of nose cones has run out, so the cones from unusable missiles will be used in the manufacture of new missiles.

Open burn and open detonation are demilitarization processes that are fully permitted at LEMC. On a recent dry and still fall day, the Pennsylvania Department of Environmental Protection gave the go ahead to detonate several warheads. As seen from a distance, 14 warheads were detonated in impressive explosions resembling dirty fireworks displays. This process takes place every day of favorable weather.

A future demilitarization program at LEMC involves a new $12 million football-field-sized building which will demil approximately 10,000 outdated missile motor rockets a year in an environmentally safe manner. Construction of the building will begin in the fall of 2011, and it is expected to be fully operational two years later. The new facility will employ up to 25 people for up to 14 years.

Outloading

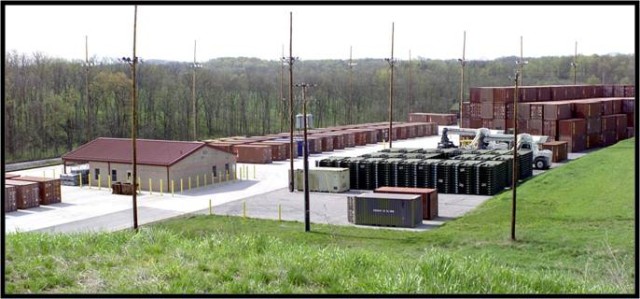

LEMC's outloading operation is another of its jewels. It possesses 27 rail docks and two containerization pads along with a facility where workers repair, reconfigure and repaint containers. There is a new less-than-truckload facility which promotes efficiency. Partial loads can be stored until they equal a full load which then is transferred to storage.

The outloading site includes a blocking and bracing facility where containers are outfitted to safely transport ammunition, and possesses the capability of loading more than 200 containers every 24 hours.

A new gate for commercial truck deliveries was opened in 2005. Instead of having to navigate the 126 miles of paved roads at LEMC, drivers can deliver loads conveniently from an interstate highway. Deliveries to the new gate also will save on wear and tear of LEMC's roads. Voelz Gate was named in honor of Staff Sgt. Kimberly Fahnestock Voelz, the first female explosive ordnance disposal Soldier and the first female Soldier from Pennsylvania to lose her life in Iraq.

Storage

Last, but definitely not least, the gem of LEMCAca,!a,,cs storage capability is extensive. Its 2.1 million square feet of facilities store 121,298 short tons of munitions, the equivalent of $9.23 billion of inventory.

In the last four years, almost 200 magazines have been refitted with new doors in order to accommodate modern forklifts that can roll right through a doorway with loads. The original doors are narrow and incorporate a barrier across the threshold.

Although MLRS demil operations will free up 100 magazines, future storage of ATACMS, GMLRS, and other missiles will utilize those magazines opened up through demil efforts.

Whether storage, outloading, or demilitarization capabilities, maintenance, testing and repair facilities or dedicated employees, every gem at Letterkenny Munitions Center lends its unique luster to the whole jeweled crown.

Social Sharing