ANNISTON ARMY DEPOT, Ala. - Anniston Army Depot is known for taking used and battle-damaged vehicles and weapons and rebuilding them better than new, but in one small shop in the Nichols Industrial Complex, depot workers partner with Honeywell to create engines that are brand new.

That partnership saw a milestone on July 23 with the completion of the 200th AGT1500 Egyptian engine.

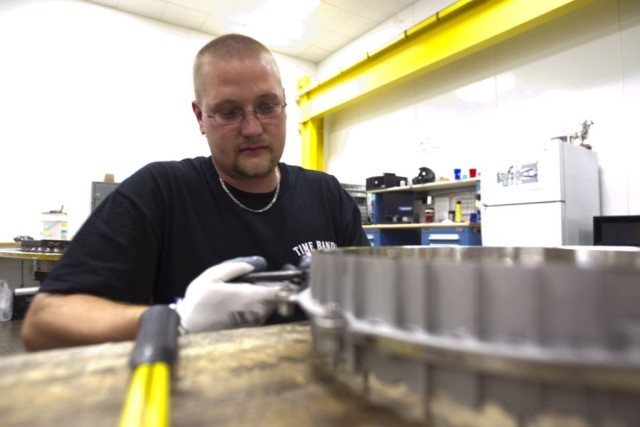

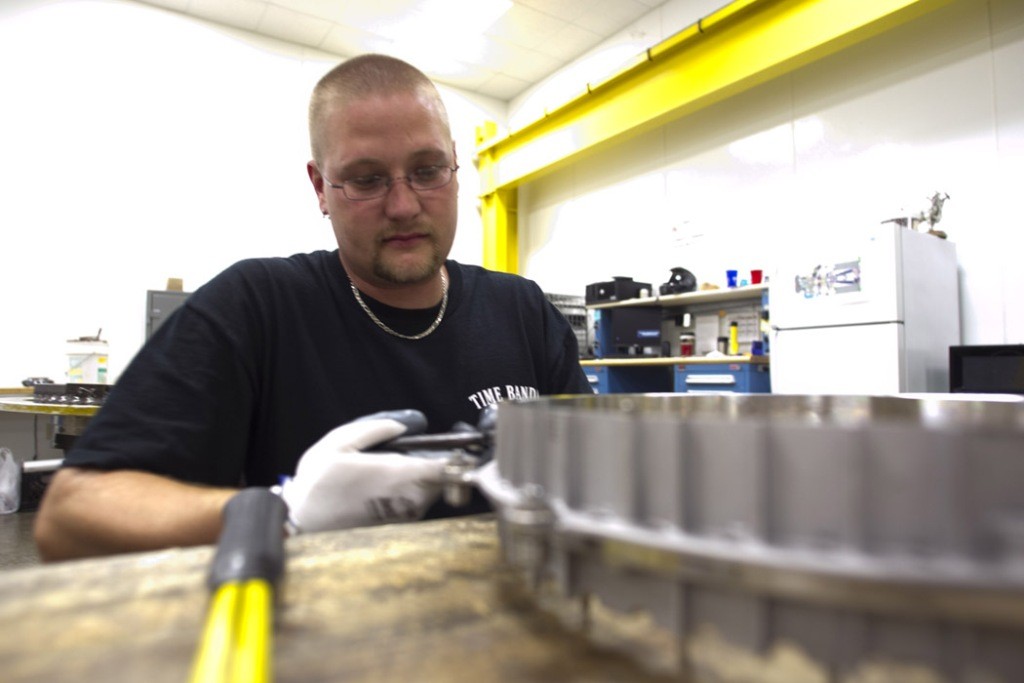

Honeywell and ANAD partnered to build new engines for the Egyptian government in 2005. Honeywell supplies the parts, technical support and the step-by-step instructions while the depot supplies the facilities and mechanics, each whom has valuable experience working on the AGT1500 turbine engine.

"It has been a good partnership between the depot and Honeywell," said Rodney Hanson, ANAD's lead mechanic in the shop. "Honeywell not only supplies the parts, they supply the procedures to build the engines, which are almost the same as those used to rebuild AGT1500 engines, but there are a few differences."

Many of those differences are in tolerances allowed both while the engine is being built and when it is tested prior to shipment.

An older engine may have parts that have been reworked, necessitating larger variances in horsepower as well as in measurements for the parts themselves. A new engine, like the Egyptian AGT1500, can be built to a stricter set of specifications.

"With reclaimed parts, a lot of the time you have to work with the part to make it work. With new parts, the engine goes together better," said mechanic Alex Rogers, who has worked on AGT1500 engines at the depot for eight years.

Orders for these new engines come in increments of 125. In December 2008, the partners completed the first set of 125 new engines. They began the next increment a month later and have approximately 50 engines left to complete. Bill Cavender, Honeywell's program manager for the Egyptian AGT1500s, said he expects the final engine of this group to be complete in 2011.

Cavender said the biggest difference between these new engines and the ones built just across the street through the Total InteGrated Engine Revitalization program is each engine's expected lifespan. Though the TIGER engines have a longer life than a typical overhaul, due to the number of new parts placed on each engine, having an engine built entirely of new parts gives it a significantly longer life expectancy.

"You should get more hours out of these engines versus an overhaul. It's just the benefit of having new versus refurbished components," said Cavender.

Before this program began, the last new AGT1500 engine was built by Honeywell in 1995.

Social Sharing