ANNISTON ARMY DEPOT, Ala. - Matt Hunter doesn't work on 70-ton combat vehicles or operate the heavy trucks and tractors that move millions of parts each year through the depot's Nichols Industrial Complex.

He plays an important role, however, in Anniston Army Depot's mission to reset, repair and overhaul vehicles and weapons for the armed forces through his involvement in a high-priority program for the Army.

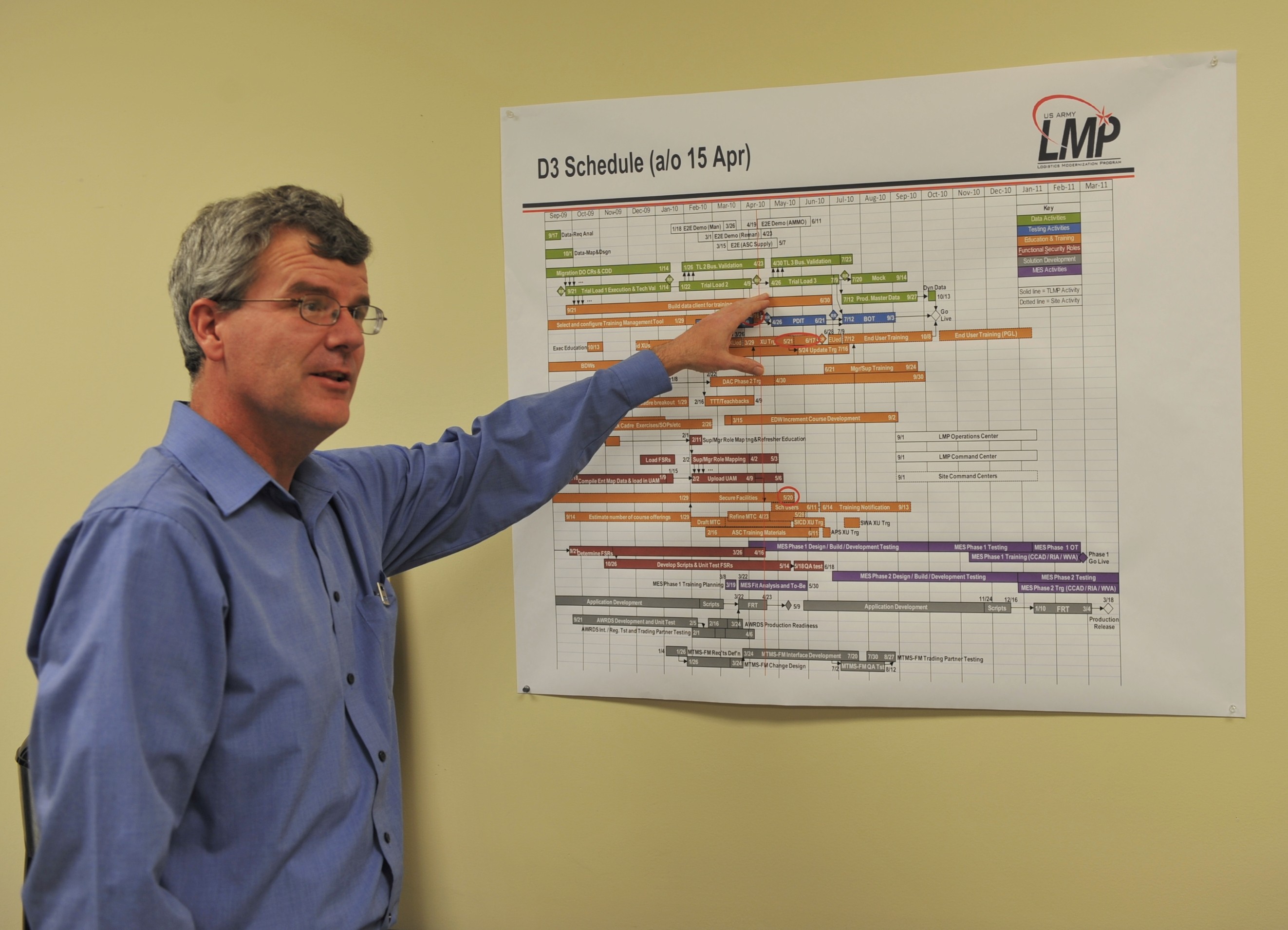

Maintaining Anniston's depot maintenance mission is dependent upon the intensity of employees here to prepare for the October deployment of Logistics Modernization Program, a business system scheduled to replace the decades-old Standard Depot System.

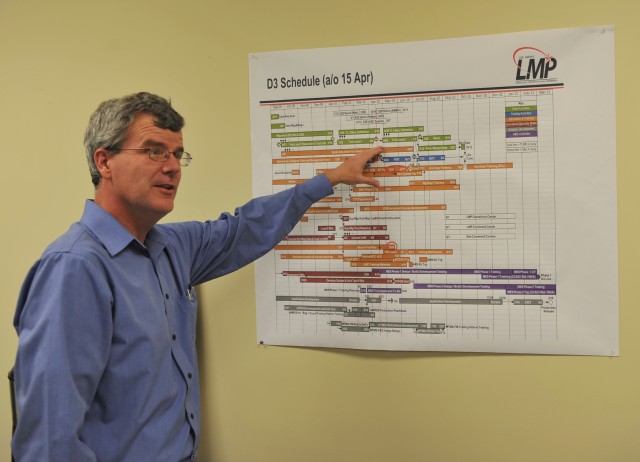

Hunter, the LMP finance lead at ANAD, and many others on depot are solely dedicated to ensuring the data used today is accurate enough to load into LMP when ANAD approaches its go-live date.

As one of the LMP subject matter experts at ANAD and other Army Materiel Command installations, Hunter has been called to assist with LMP implementation at non-AMC organizations like Defense Finance and Accounting Service.

"Matt's experience in the finance arena has put him into a position to work with LMP users at other sites. The depots and arsenals that have already deployed LMP depend upon is expertise," said Gilda Knighton, business transformation manager for LMP at ANAD.

That experience is due in large part to his work in 1995 to deploy the Standard Industrial Fund System-the financial module of SDS-at Rock Island Arsenal, Ill. Because all financial reports and data come from SIFS, Hunter brings a background in system reporting to the LMP deployment process at ANAD, where he has worked since 2006.

After a 1997 breakthrough, Hunter was in high demand. He figured out how to reconcile the ending work-in-process to the detail supporting records. Consequently, he received requests from about a dozen installations to assist with WIP reconciliation and provide training on SIFS.

When the Army signed the LMP contract with Computer Science Corporation in 2000, Hunter was pulled in to assist the first deployment sites, which included Tobyhanna Army Depot, Pa.

The most sizeable lesson learned from Hunter's history with business system conversions places the focus on clean data.

"Data cleansing is an instrumental activity in ensuring the success of LMP deployment at Anniston," said Hunter. "The proof is in the trial loads."

The depot has been loading its SDS data into LMP test systems to generate reports showing where problems and errors exist.

He said Anniston's data is "cleaner" than all the other third (and final) LMP deployment sites.

"His efforts will lead to a smoother transition to LMP," said Knighton.

"We need a concerted effort from everyone using SDS to correct what's causing these errors in our trial loads so our records are in the best shape possible for LMP go-live," Hunter said.

Social Sharing