underwent its 17th and final developmental test at U.S. Army Yuma Proving Ground in mid-January. The test used a 44-foot long dart attached to a pallet

instead of a mock... VIEW ORIGINAL

YUMA PROVING GROUND, Ariz.--- From the heady days of the Apollo program to the present, U.S. Army Yuma Proving Ground has lent its infrastructure and testing expertise to the National Aeronautics and Space Administration (NASA).

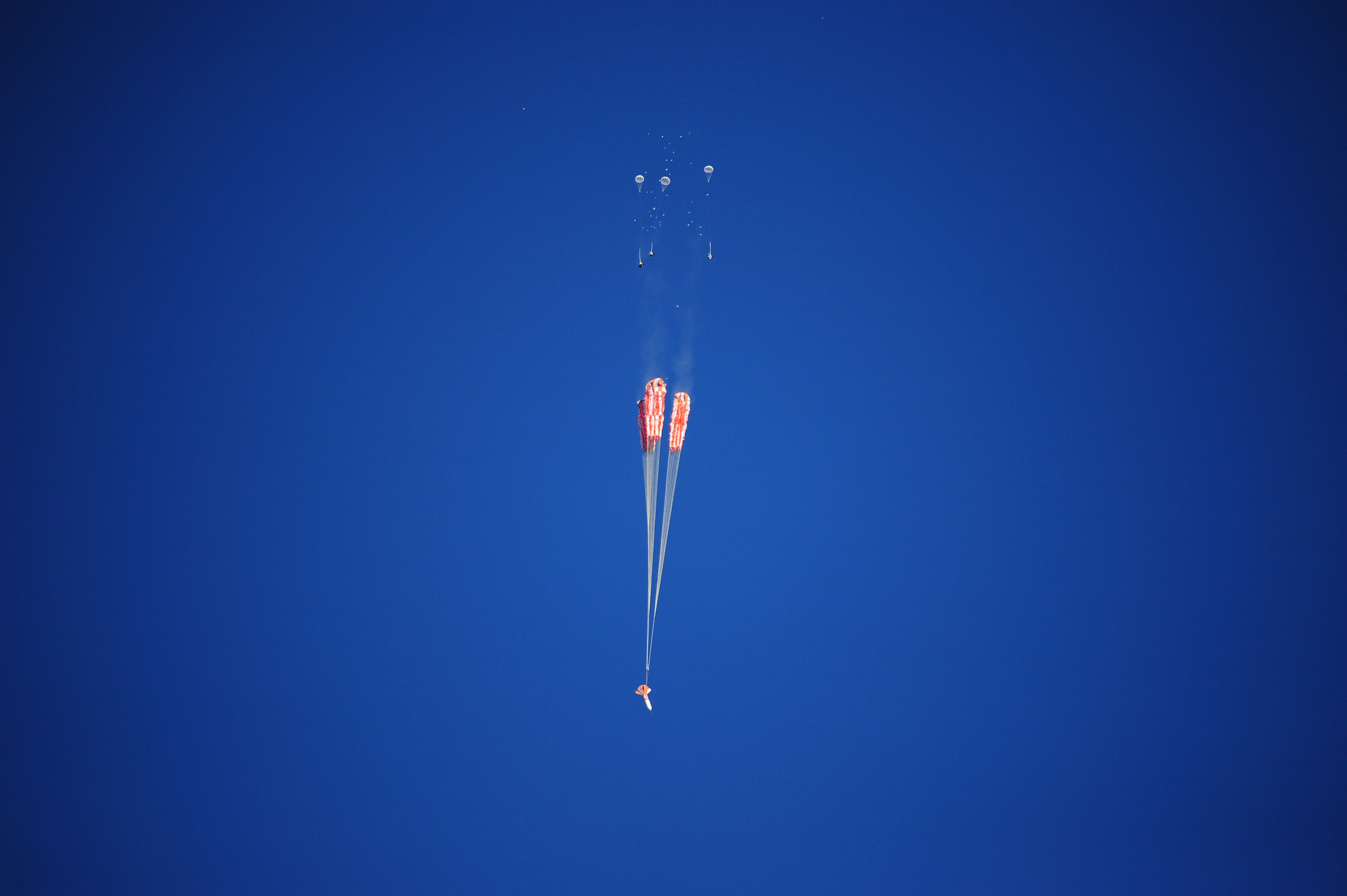

In 1966, the Mobility Test Article, an early version of the lunar rover, went through developmental testing on YPG's vast ranges. Fifty years later, the Capsule Parachute Assembly System (CPAS) for the Orion space capsule was dropped early this month from 30,000 feet in the system's 17th and final developmental test.

YPG's contribution to space exploration isn't finished, however: qualification testing for the CPAS will begin this summer, and YPG personnel are ready for the task.

Little change is envisioned regarding future NASA parachute testing coming to YPG.

"We will be providing the same support for NASA during qualification testing," said Ryan Fraser, test officer, "and they will be identical tests as far as our support is concerned."

The astronauts who will ultimately fly aboard the Orion capsule count on the CPAS to land them safely back on Earth when their mission is complete. Each of the system's three main parachutes have canopies made with 10,000 square feet of broadcloth nylon, and the rope that makes up the parachutes' cord is made of Kevlar, the strong synthetic fiber used in body armor.

"The parachute system for Orion is comprised of 11 different parachutes, and they all have to operate in a highly choreographed fashion," said Charlie Lundquist, deputy program manager of the Orion program. "Parachutes are very dynamic things: they flop around in the breeze, and the vehicle moves all over the place. That is very difficult to model, and there is no substitute for real world testing. That's why Yuma is so critical."

The CPAS system is designed to deploy sequentially and pass through two stages prior to being fully open: after hurtling back into Earth's atmosphere, two drogue parachutes deploy to slow the 10-ton capsule prior to main parachutes decelerating the capsule to less than 20 miles per hour.

Meanwhile, the extreme friction of the capsule hurtling back into Earth's atmosphere at such a tremendous speed means its exterior heats to more than 4,000 degrees Fahrenheit. The system is designed with redundancies meant to protect the safe landing of astronauts even in extreme scenarios such as two parachutes failing, or a catastrophic mishap shortly after takeoff, all of which were tested at YPG.

"Over the 17 drop tests that we have done out here, we have learned a lot and incorporated those lessons into the designs of the parachutes," said Lundquist. "I contend that this system is the safest spacecraft recovery system ever designed. We are going to need that high reliability for the very demanding missions in store."

Given that the Orion capsule and CPAS system had a successful first flight in outer space in December 2014, some folks may assume that subsequent developmental tests were anticlimactic. NASA engineers, however, say this is not at all the case: in addition to being able to outfit the test vehicle with far more instrumentation and cameras than would be possible if it was coming from space, testing over land at YPG makes recovery and examination of the parachutes easier than when it lands in the ocean, as in a real space mission.

Once the January drop was completed, personnel fanned out and carefully recovered the massive parachutes and lines from the desert floor, gathering them slowly and methodically to allow testers to evaluate any damage that may have occurred during landing. As the packed parachutes made the journey back to the Air Delivery Complex, where they were suspended from a high ceiling and carefully studied, workers from YPG's motor pool used a large crane to lift the massive test capsule onto a lowboy trailer for transport back to Yuma.

The developmental phase of the program is now complete, but more evaluations remain. Qualification tests start at the proving ground this summer, and NASA officials expect more than two years of testing remain before the CPAS is fully certified.

"As a test officer, it is great to see the NASA team complete this phase and move into their qualification testing phase," said Fraser.

For their part, NASA is looking forward not only to sending astronauts aboard the Orion to the moon and Mars, but to inspiring the next generation of young scientists and engineers.

"One of NASA's missions is to excite young people about technology, science, engineering and math," said Lundquist. "I was around when the Apollo astronauts landed on the moon, and that was very influential in steering me toward the technical disciplines."

Social Sharing