Detroit Arsenal, WARREN, Mich., Sept. 29, 2015 -- All over the world, companies, as well as the military, face real challenges in delivering better purchasing and contracting value for public dollars. Government debt, budget cuts and, in some parts of the world, outdated and corrupt practices make this task a difficult one. There are, however, initiatives underway to find, leverage and share purchasing and contracting best practices by building partnerships between industry and government.

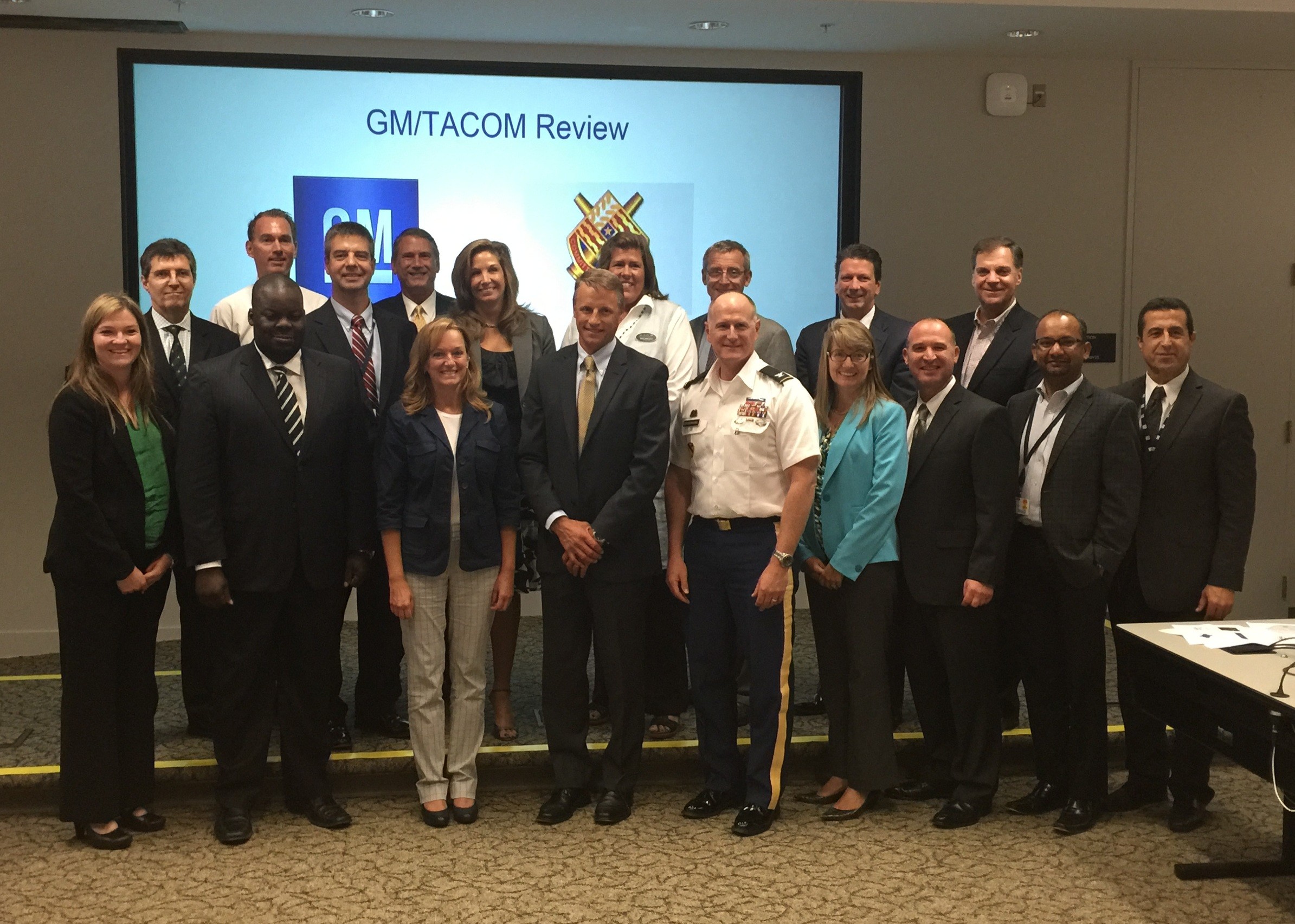

One such initiative began recently at the General Motors Technical Center, also located in Warren, Mich. Soldiers and Department of the Army civilians from Army Contracting Command -- Warren (ACC-WRN) participated in a leadership development seminar with their counterparts from the GM Tech Center. During the session, GM'S Global Purchasing and Supply Chain (GSPC) executives shared strategic insights and best practices on supporting a global network of customers and stakeholders with contracted goods and services.

GPSC is responsible for procuring all goods and services GM and its joint venture and alliance partners use in their business regions around the world. The event was planned and executed at the request of Kristan Mendoza, executive director, ACC-WRN, as part of an initiative sparked by Maj. Gen. Gwen Bingham, commanding general, U.S. Army TACOM Life Cycle Management Command. The aim is to develop relationships with industry and community neighbors in the metro Detroit area.

After brief introductions and a welcome from Shilpan Amin, executive director, GM Purchasing Program Management, Col. Robert Brinkmann, military deputy, ACC-WRN, provided an overview of the Army's command structure, showing the relationships between the Army Contracting Command, the TACOM LCMC, and the Program Executive Offices they serve; and how efforts at the Detroit Arsenal support Soldiers around the world. Following Brinkmann's overview, GM executives discussed topics ranging from how purchasing is integrated into GM's supply chain, to efforts focused on improving supplier relationships.

The event concluded with a question-and-answer session in which leaders from both organizations engaged in a lively discussion about workforce development and supplier/contractor performance and evaluations.

One major takeaway from the seminar was how GM buyers engage early in the buying process with both product engineering teams and strategic suppliers. This is to ensure requirements are understood and supplier capacity is available.

Another best practice is GM's use of supplier scorecards to measure contractor performance. Vito Zuccaro, chief of the Force Projection and Tools Contracting Division, ACC-WRN, said, "It is reaffirming and inspiring to see that our organization is on the right track with our strategic objectives to better serve our customers.

Although our products may be different from GM's," he continued, "we share the same fundamental buying functions and organizational objectives, such as acquisition planning and integration, contractor management, and workforce development."

Master Sgt. Douglas Collins, contract specialist, 923rd Contracting Battalion, added, "I thought it was interesting to see that their [GM's] acquisition process and the military's are so similar. Prior to the visit, I wasn't sure what to expect, but it was nice to see firsthand that our contracting career field has a direct correlation to industry practices."

Now that a relationship between the organizations has been established, both Collins and Zuccaro would like to see the program expanded. As far future engagements with GM, Zuccaro stated, "It would be beneficial to have one-on-one or small-group discussions with our peers [at GM] to better understand how they manage their workforce and workload -- and to see what systems they have established to streamline requirements."

Collins added, "I would like to hear more about how they compare their requirements among their suppliers to see if any of their practices are applicable to what we do at ACC-Warren."

Social Sharing