WASHINGTON, D.C. -- The Aviation and Missile Command is a big winner this year in the Department of Defense Value Engineering Achievement Awards.

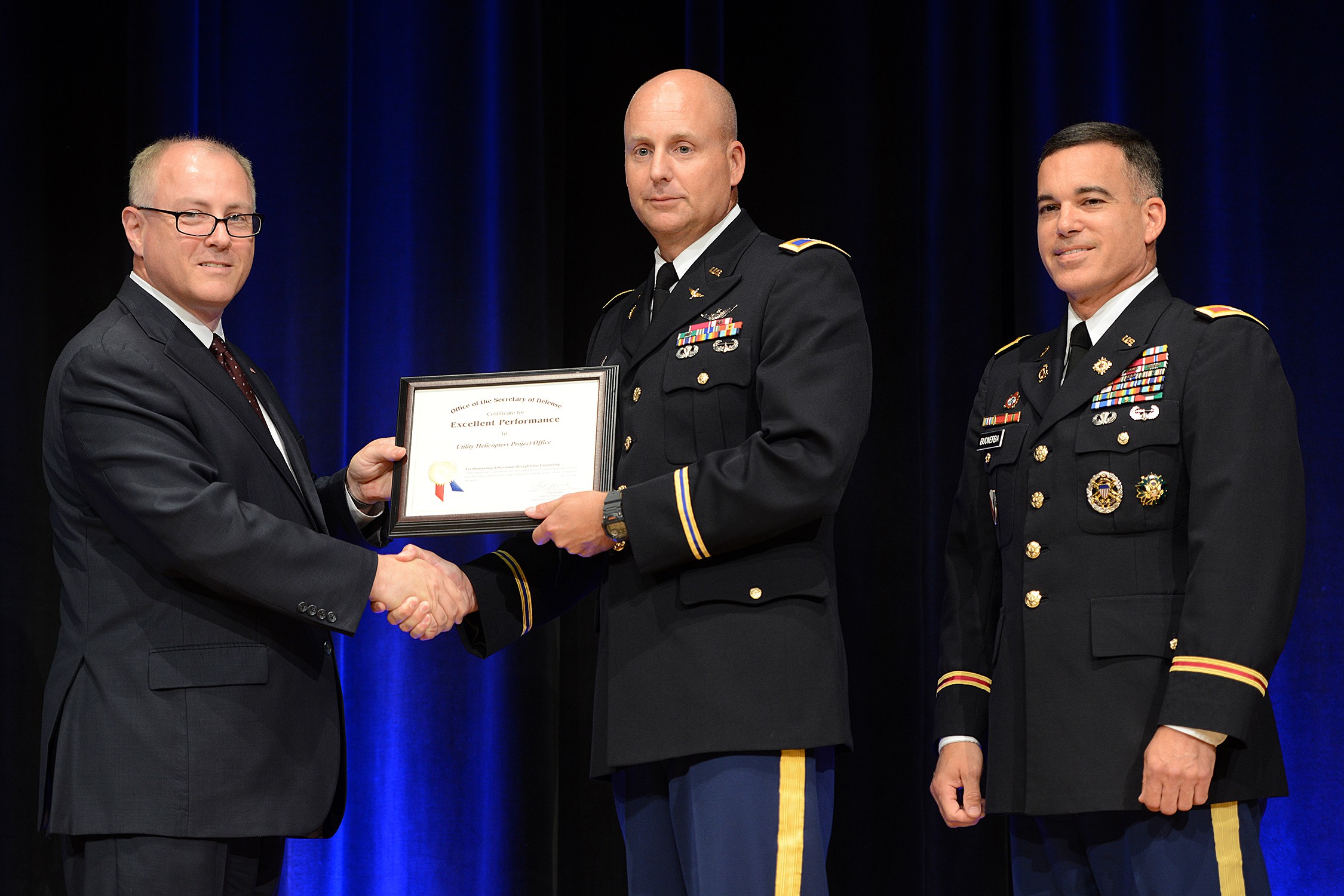

AMCOM and its partners were presented with four VE awards on Thursday. The awards were presented by Stephen Welby, deputy assistant Secretary of Defense for Systems Engineering, during a ceremony at the Pentagon.

AMCOM won the organization award for its "extensive and extremely successful" value engineering program in 2014, and three of its team members -- the Utility Helicopter Project Office, Program Executive Office for Aviation, the Lower Tier Project Office, Program Executive Office for Missiles and Space, and the Maintenance Engineering Division of the Aviation and Missile Research, Development and Engineering Center's Aviation Engineering Division -- also won awards.

"We have had a value engineering program as long as I can remember," said Bill Andrews, acting executive director of the AMCOM Logistics Center, who accepted the organization award on behalf of AMCOM.

"It has evolved organizationally to where our value engineering process is really a team process. We partner with AMRDEC, the PEOs and other Redstone Arsenal tenants that we traditionally do business with to focus on value engineering. We rely heavily on this team to be successful."

The Value Engineering Program through DoD uses engineering principles to reduce the cost of defense systems while improving performance for the Soldier. In fiscal 2014, value engineering created $5.5 billion in savings, according to Robert Gold, the DoD's director for the Engineering Enterprise. Since 1980, it has achieved more than $55 billion in savings and cost avoidance.

In presenting the awards, Welby said that value engineering is a critical component of the DoD's "Better Buying Power" initiative, which is focused on improving value and reducing costs throughout the life cycle of U.S. defense systems.

"So what exactly is value engineering? Simply put, it is identifying and eliminating unnecessary cost while maintaining or improving performance," Welby said. "Those being honored analyze the functions of systems, equipment, facilities, services and supplies. They ask critical questions about the performance and the associated cost of a particular system and analyze methods of cost saving without sacrificing performance."

At AMCOM, the value engineering program is spearheaded by Tom Reynolds, who works with AMCOM's partner organizations to determine which individuals and organizations to submit for possible recognition. This year, there were the DoD-offered Value Engineering awards in five categories for each military branch along with the Defense Logistics Agency, Defense Information Systems Agency and the Missile Defense Agency. Of the five Army categories, AMCOM won four. Another Team Redstone tenant -- the Missile Defense Agency -- won in all five categories. The two

Redstone tenants competed with DoD organizations worldwide for the awards.

"AMCOM has won at least one DoD Value Engineering award every year for the last 24 years," said Reynolds, AMCOM's Value Engineering program manager. "But Team Redstone really has done an outstanding job this year. Throughout the Army, the Value Engineering Program has thrived and continues to thrive. But, right now, Team Redstone has the most vibrant program."

When reviewing programs during the nominating process, Reynolds said it is most common to focus on how much money the project saves. For Redstone Arsenal, the AMCOM and MDA projects represent a saving of $235 million for DoD. Other critical benefits are also considered, such as mitigating obsolescence, improving quality, expanding the industrial base, reducing weight, minimizing cycle times, developing new repairs, enhancing performance, updating technology, shrinking inventories, decreasing administrative burden, optimizing power consumption and increasing readiness.

The following awards were won by AMCOM:

• Organization award -- AMCOM personnel collaborated with the Program Executive Office for Simulation, Training and Instrumentation, Communications Electronics Command, Special Operations Command, Forces Command, Training and Doctrine Command, National Guard and Tank Automotive Command to complete 124 value engineering projects with a net savings/cost avoidance of $235 million.

• Program/Project award: The Utility Helicopter Project Office, Program Executive Office for Aviation, reported a savings of $29.814 million from two value engineering.

• Team -- AMRDEC's Maintenance Engineering Division at Corpus Christi, Texas, reported a savings of $66 million with 91 value engineering projects completed.

• Special -- Lower Tier Project Office, Program Executive Office for Missiles and Space, reported a $23.6 million savings over the next three years in the design of a new Patriot Tactical Trainer across three years. The new trainer will replace a trainer that has a much higher cost to produce.

"Value engineering is important, first because we need to identify issues and get those issues resolved to make Soldiers' lives better," Reynolds said.

"Second, from the cost savings shown in the nomination packets, value engineering allows us to find ways to save money for the taxpayer while still providing equipment that is effective and efficient for the Soldier. That's particularly important in these austere times. And, thirdly, this is a program that involves a lot of people who bring their ideas to the table. With that, a synergistic effect happens that turns into much better results."

It's very rewarding, Andrews said, to have the AMCOM team recognized at the DoD level through the Value Engineering Achievement Award program.

"Our technology lends itself to these awards because our engineers are highly motivated to be involved with value engineering," he said.

"These awards validate for this community and our team that the talent level and the opportunities are here to continue to excel."

Each organization within AMCOM and its partners establish an approach to meet their value engineering goal every year, Andrews said. Engineers look for trends, and ways to be more effective and more efficient while using the system engineering process. The value engineering ideas must first be proposed, and then they are validated, developed and determined if they are sustainable, a process that can be three to five years in the making, Andrews said, adding that the complexity of missile and aviation systems makes value engineering a significant challenge.

"It's everything from something that's technical where you are trying to improve a system to a simple cost savings measure. It's usually dealing with equipment very late in its life cycle. Often, it has to do with reclaiming or reutilizing materials," he said. "We are making improvements while ultimately providing savings to the taxpayer."

With every award won, there comes a team of dedicated AMCOM employees.

At Corpus Christi Army Depot, where AMRDEC's Maintenance Engineering Division supports AMCOM's life cycle management goals, Kevin Rees leads a team of 62 employees responsible for the airworthiness of all helicopters that go through the depot for maintenance.

"Each aircraft component has an overhaul manual that requires parts to be replaced at certain times. Those parts have to be thrown away," Rees said. "We worked to repair and reclass those parts so they wouldn't have to be thrown away. We used new technologies for welding repairs, composite repairs, plating repairs, metal spray repairs and technology repairs. There are 20,000 to 25,000 engine parts, and we are working to reclaim those parts when they have to be replaced."

Typically, the reclamation project saves more than $50 million annually. In fiscal 2014, the savings reached $60 million.

While the Corpus Christi employees take the lead in the parts reclamation program, they rely on their partners back at Redstone Arsenal to assist in determining how parts can be reclaimed.

"AMRDEC's Aviation Engineering Division at Redstone has the experts in engineering and structural repairs. Our engineers here really enjoy working value engineering because they go out to the machine shop and see the engineering really happening. It's a very hands-on job for them," Rees said.

Sometimes new technologies -- such as the cold spray technology -- make it possible to repair parts that haven't been repairable with the older technologies, he said. Other times older technologies are applied in different ways to make repairs possible.

"Value engineering is so important to what we are doing, especially in these days with budgets coming down. It's nice to be able to save cost while also improving quality," Rees said. "But, it goes beyond that for us as a team. We all have an intrinsic motivation. We want to do well for the taxpayer and the Soldier. We take a lot of pride in our work. Getting recognized isn't our motivator, but it does encourage us."

It's a natural step in the value engineering process to submit projects for award recognition, Reynolds said, making it more institutionalized at an engineering heavy installation like Redstone Arsenal. By U.S. law, every military command and government agency is required to participate in the DoD Value Engineering Program.

"With missiles and helicopters, you can't touch them without an engineering review. And in that review, you do a function analysis, use brainstorming techniques to come up with solutions and address all the technical ramifications through a very collaborative environment," Reynolds said. "We have continuously presented good projects for value engineering awards. It's a very active tradition for us."

AMCOM often wins value engineering awards because of the employees who work for the organization and the support for value engineering from leadership.

"The hierarchy and general culture here supports value engineering," Reynolds said. "We're very innovative and always looking to do the best for Soldiers. That permeates the entire organization."

It's a culture that senior leadership at the DoD level is proud to recognize.

"In concert with sound acquisition practices, value engineering helps us to keep our war fighters the best in the world," award presenter Welby said.

"With that as a goal, the President and Secretary of Defense are clear in their direction that taxpayer dollars be spent only on necessary and cost-effective programs … that ensure a high quality of product, supply and service, delivering the best value for taxpayers and war fighters alike. That is the fundamental concept of value engineering."

Social Sharing