The 21st Theater Sustainment Command and U.S. Army Europe (USAREUR) have successfully completed multiple Lean Six Sigma (LSS) projects as part of a focus on fiscal stewardship and continued readiness. One such project used LSS to optimize the theater-level organizational clothing and individual equipment (OCIE) inventory, resulting in cost avoidance, improved processes, and a right-sized inventory.

EQUIPMENT IN USAREUR

USAREUR is a story of continual change. Its force swelled to 212,000 Soldiers in 1989 and decreased to around 30,000 Soldiers by the start of fiscal year 2015. Troop reductions and coinciding base closures eliminated four major installations over the past two years.

Prior to the most recent base closures, theater equipment stocks had grown to support modernization efforts and operational deployments. These stocks equipped Soldiers with improved clothing that had been tested over the previous decade of war and found to be more comfortable, versatile, and durable.

Theater-level sustainment operations aimed at providing effective warfighter support with greater efficiency led to multiple efforts to balance capability, capacity, and resources. These efforts led to an LSS project to examine theater-level management of OCIE.

WHY LSS?

Complex problem sets often require sophisticated evaluation and management skills. Many complex problem sets arise from optimizing the complex global supply chain that links the strategic industrial base to tactical formations.

Specifically, optimizing theater-level OCIE inventory and processes requires complex analysis and detailed management at the strategic, operational, and tactical levels, so this task was a perfect candidate for using LSS tools.

LSS tools combine the power of both Lean manufacturing (reduce waste) and Six Sigma (reduce variation) in an effort to achieve process improvement.

Lean manufacturing principles date back to the Ford production line of the early 1900s and were made famous by Toyota's production system developed in Japan by Taiichi Ohno after World War II.

Six Sigma was developed by Motorola in 1986 and is central to the business strategies of many industrial sectors. Its name is derived from the probability of events across a statistical set. In a Six Sigma process, 99.99966 percent of the products manufactured are expected to be free of defects, meaning 3.4 defects per 1 million opportunities. Required process controls are so stringent that most companies strive to operate at three sigma, or 99.73-percent defect-free.

Sophisticated tools are essential in order to achieve this level of statistical fidelity and continually improve in a complex environment. The Army has used LSS tools since 2006 to effect wholesale organizational, process, policy, and procedure changes across its formations. From the most basic standpoint, the LSS method has five phases:

• Define the problem.

• Measure key aspects of the current process.

• Analyze the data to investigate and verify cause-and-effect relationships.

• Improve the current process.

• Control the new process to prevent deviations.

The 21st Theater Sustainment Command, in coordination with USAREUR, the 405th Army Field Support Brigade, and the Theater Logistics Support Center-Europe, used the power of LSS tools at the strategic, operational, and tactical levels to achieve results that addressed the challenge of theater-level OCIE inventory management.

OCIE OPERATIONS IN USAREUR

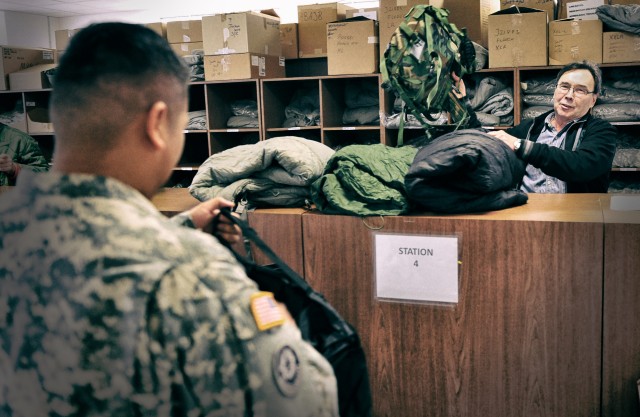

USAREUR uses a hub and spoke model, centralizing management of OCIE operations in Kaiserslautern, Germany, at the OCIE Sustainment Center (OSC). The 21st Theater Sustainment Command manages the OSC as a central warehouse to hold and redistribute inventory for all central issue facilities (CIFs) in Europe.

Centralized distribution within the USAREUR footprint reduces customer wait time and demand satisfaction time. Instead of each CIF reaching back to the national industrial base for supply replenishment, the OSC maintains stocks to satisfy customer demand, potentially reducing shipping times by many months. The OSC processed 3,762 lines, more than 1.1 million pieces, and over $125 million in equipment during fiscal year 2013.

Each CIF is responsible for the direct issue of OCIE and the processing of returns. Having the CIFs dispersed across Europe where concentrations of Soldiers are located ensures that equipment will be available for Soldiers when they need it. Main CIFs have additional capabilities, such as the ability to ship directly to continental United States (CONUS) installations and to perform laundry operations.

PROJECT PHASES

To address theater-level OCIE process improvement, a team looked at the current process and potential courses of action to increase efficiency and lower costs. A cost-benefit analysis of OCIE sustainment led to the formation of an LSS team and the project launch, which resulted in $14 million in cost savings within 10 months. The project was divided into the five LSS phases.

DEFINE. The first step in LSS is to define the problem. To do this, the project team completed an inventory analysis of the OSC to determine the average days of supply (DOS) on hand.

The Army manages OCIE through a database residing in the Installation Support Modules (ISM) system. ISM supports logistics business functions associated with the management and accountability of OCIE. Using the exportable feature of ISM, an Oracle database called Discoverer, the LSS team analyzed the lateral transfer register files to generate the demand data for each piece of OCIE.

Then, using a series of Microsoft Excel-based lookup tables, the team determined the DOS by taking the inventory currently available for issue and dividing it by the average daily usage. The project scope was narrowed by considering only items on the OCIE standard issue list, meaning that they are issued to every Soldier. As a result, the team determined that the DOS average was an astonishing 2,203 days, or about 6 years.

MEASURE. During the measure phase, the team determined the average DOS and compared that to historical data going back 15 months. The result was a capability analysis that compared the DOS average over time with the Department of the Army standard of 180 days.

To account for this shift, an index for process capability (Cpk) was used to account for the dynamic mean shift in the process, or the amount that the process is off target. Typical goals for Cpk are greater than 1.33 or 1.67 for safety-related items. The LSS team determined the resulting Cpk was -35.7, meaning the process was nowhere near capable.

For example, think of parking in a garage. A Cpk of 1.67 means that you have parked your compact car directly in the center of the one-car garage, where a Cpk of -35.7 means that you have parked your car in the neighboring town.

ANALYZE. The third project phase was to analyze the data and determine the root causes that were affecting the DOS. The LSS team used a series of tools to do this, including developing a cause and effect diagram (or "fish bone chart") and conducting Pareto analysis, failure modes and effects analysis, and analysis of variance.

Results of the Pareto analysis and analysis of variance determined that cold weather and protective equipment accounted for 76.5 percent of the total days of supply across the data sample. The highest DOS belonged to the sleeping equipment category, which had an astounding average of 8,837 days.

The team then used a multi-voting technique to determine the critical root causes influencing the data and put them in order based on risk priority number, which was based on the severity, occurrence, and detection. The complex process to dispose of excess inventory and a lack of standard operating procedures were the top root causes, which the team looked to correct during the improve phase.

IMPROVE. In the fourth project phase, improve, the LSS team determined the improvements for the process and piloted an excess inventory reduction plan. An initial list of 71 potential solutions was narrowed down to 10 based on benefit and effort analyses.

These solutions included strategic-, operational-, and tactical-level OCIE working groups, updated operating procedures, improved training, performance metric development and management, organizational inspection programs, updated contingency levels, and pre-positioning of CONUS shipments.

Team members voted on benefit and effort required for each solution and also selected their own personal choices. The team focused on solutions with high value that were easier to implement.

The LSS team implemented these solutions across three levels: strategic (led by USAREUR), operational (21st Theater Sustainment Command), and tactical (405th Army Field Support Brigade). The pilot inventory reduction effort resulted in over $5 million worth of OCIE removed from stock and then redistributed to six CIFs in the United States with valid requirements.

CONTROL. The final phase was to control the new process to prevent deviations. During this phase, the LSS team redistributed an additional $9 million in OCIE by using the new process map developed during the improve phase. The control phase also included a long-term implementation plan, outlining the frequency of each process control measure and responsible organization.

QUICK WINS

A key tenet of LSS is to identify and implement improvements that can be made quickly and inexpensively. These are known as "quick wins." The OCIE project team identified several during the course of the project.

AUTOMATED INVENTORY MANAGEMENT. ISM allows automated inventory management functionality by tracking demand data and setting reorder points for items. However, for ISM to generate that data, it requires a completed issue transaction.

Since the process for inventory transactions between the OSC and CIFs within USAREUR was through lateral transfers, and not issue transactions, none of this data was captured in ISM. The LSS project team recognized fixing this as a potential quick win and engaged programmers from the Program Executive Office Enterprise Information Systems. The programmers completed a software modification that took effect two months after the start of the LSS project.

TOTAL STOCKAGE ALLOWANCE. The LSS team reviewed the automation results line by line and updated each item's contingency level, which is the amount specified to cover non-demand-supported requirements. Contingency levels, along with the demand-based retention levels and requisition objective levels, determine the total stockage allowance.

The purpose of this allowance is to help identify materiel available for lateral transfer between CIFs. The project team used the updated total stockage allowance data to generate a follow-on excess reduction list worth $27 million for the next fiscal year.

STREAMLINED SHIPPING OPERATIONS. The OCIE project team enabled a trans-ship process to reduce the number of steps required to ship items from CIFs in Europe to CONUS.

In the new process, excess inventory is sent to the OSC's shipment staging area, where the Theater Logistics Support Center-Europe completes the required steps of pallet construction, configuration, cleaning, and inspection. These steps are built into the process lead time, and there is only one lateral transfer transaction from the shipping CIF to the receiving CIF in the United States. The trans-ship process eliminates the need to return items to stock and pull them out on a separate transaction.

In just eight months, the project team completed each of the five LSS phases and achieved results that vastly exceeded expectations. The 21st Theater Sustainment Command, in coordination with project team members, facilitated the movement of $14 million in excess OCIE inventory shipments to six different installations in the United States. The redistribution of OCIE offset future requirements at these installations, saving the Army money.

The project achieved operational benefits by improving the existing process. The team's actions reduced inventory, transactions, and storage space required for OCIE sustainment operations across Europe.

Additionally, the quick wins that the project team implemented enabled automated inventory management and streamlined the theater distribution process. Through the effective use of LSS tools, the team saved millions of dollars and improved OCIE operations across the continent.

_____________________________________________________________________________________________________

Maj. Jeremy Weestrand is the executive officer to the commanding general of the 21st Theater Sustainment Command in Kaiserslautern, Germany. He holds a bachelor's degree in international relations from Concordia College, a master's degree in organizational psychology from Columbia University, and master's degree in business/supply chain management from the University of Kansas. He is an Army certified Lean Six Sigma green belt.

Jeffrey D. Gilbert is an operations research analyst with the 21st Theater Sustainment Command. He holds a bachelor's degree in mechanical engineering from Penn State and a master's degree in management/logistics management from the Florida Institute of Technology. He is an Army certified Lean Six Sigma black belt and master black belt candidate, a member of the Army Acquisition Corps, and level III certified in both test and evaluation and life cycle logistics.

_____________________________________________________________________________________________________

This article was published in the May-June 2015 issue of Army Sustainment magazine.

Related Links:

Army Sustainment Magazine Archives

Social Sharing