PICATINNY ARSENAL, N.J. (March 9, 2015) -- In 2011, Picatinny Arsenal made a leap from traditional, black and white manuals when it introduced an interactive manual called the Interactive Electronic Technical Manual (IETM) for the Spider XM7 Network Munition Dispensing Set.

Now, the manual has returned for another system: the XM153 Common Remotely Operated Weapon Station, or CROWS.

The interactive manual is an in-house project from the Logistics Research and Engineering Directorate of the Armament Research, Development and Engineering Center.

"The CROWS IETM is the most advanced technical manual ARDEC has ever developed. It has proven to increase access to critical repair information, which will certainly maximize the operational availability of the end item in the field," said Nikolaos Mavrakis, Chief of the Systems Support Engineering Branch at the directorate.

"A talented group of technical writers, maintenance engineers, provisioners, and illustrators contributed to the development of this IETM."

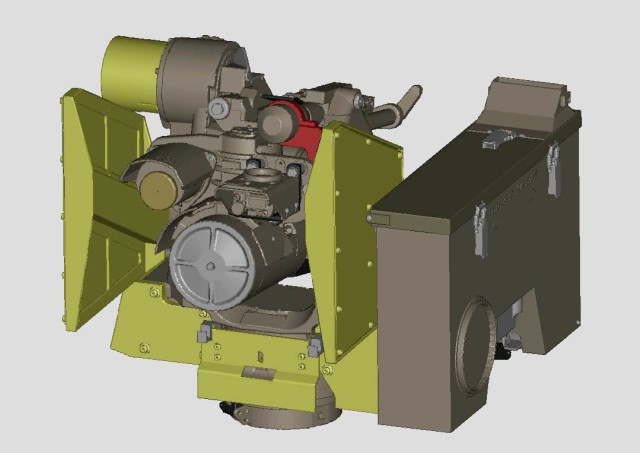

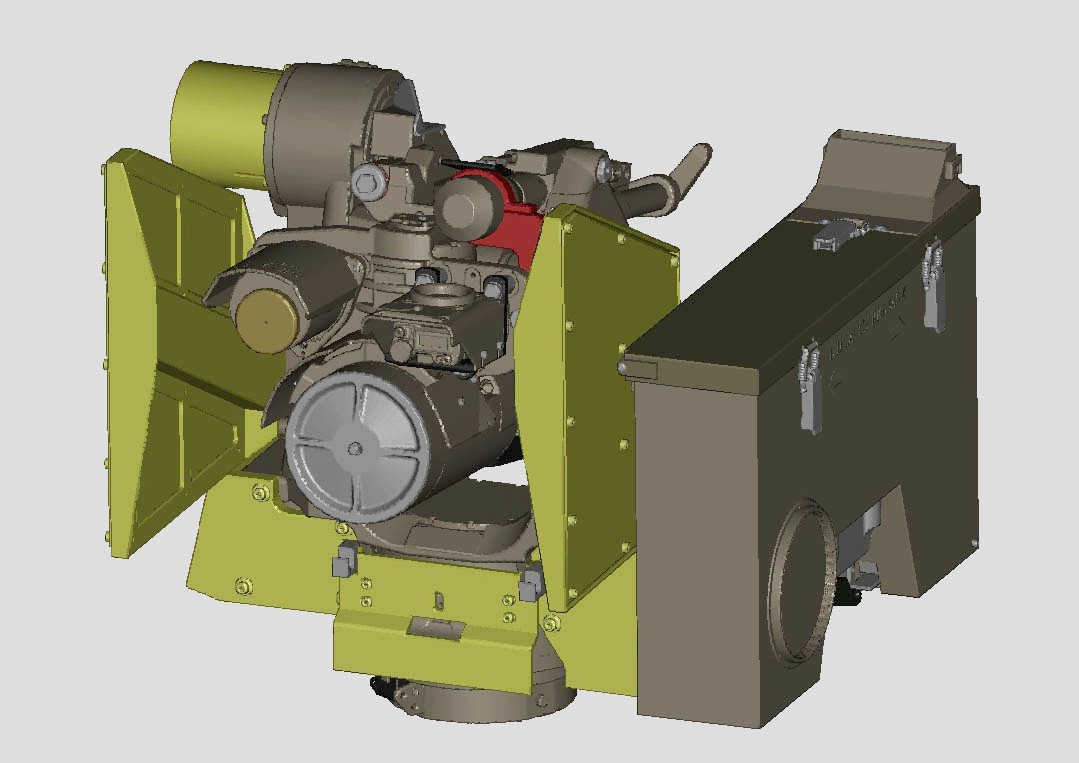

The CROWS is a remotely operated system that provides the capability to remotely aim and fire a suite of crew-served weapons. It is compatible with weapons, such as the M2, Mk19, M240 and M249--machine guns and grenade launchers. The system also minimizes the warfighter's exposure to hostile events, such as improvised explosive devices.

The manual provides the ability to view a system or component down to a basic level of detail, allowing Soldiers to perform common maintenance tasks on CROWS more easily, including inspection, assembly and disassembly.

The IETM also instructs Soldiers on the correct sequence needed to complete a task, showing step-by-step processes required to become proficient in maintaining the system.

As a result, this interactive manual provides warfighters with continuous learning opportunities and builds a familiarity with CROWS.

The interactive manual for CROWS has several enhancements over previous interactive manuals:

• Clearer, high-quality 3-D animations

• New, "Google-like" search engine with spell-check

• Increased user-friendliness for navigating the interactive manual

• Improved performance and startup time

"We took the CROWS system and completely disassembled it," explained Thomas Kallopoulos, a maintenance and system support engineer. "We measured all the components and then created a 3-D model to give users a visual aid inside the technical manuals. Now they [the users] can pull apart the system electronically, rotate it, and change all the angles.

"We also created animations with these models that take all the steps and show users how to use it," added Kallopoulos. "So, [the users] can take IETM, click on a task and see it performed on screen before they physically do it on the system. It gives the warfighter an idea of what to expect before completing a task. It helps them visualize it."

Maintaining effective supply operations for parts and manuals has long been vital to Army readiness. However, unless proficient repair skills and replacement parts are available, the most technologically advanced system may not perform when needed.

With the IETM, Soldiers can implement and distribute system and procedures updates with ease. A Soldier can also download the IETM through the Logistics Support Agency's website, which further reduces the time for a Soldier to acquire an updated interactive manual.

"The absolute best feature of the system is the 3-D view," said Sgt. 1st Class Robert Nutter, a 91B wheeled vehicle mechanic from the 250th Brigade Support Battalion, New Jersey National Guard.

"In older IETMs, it's not proportioned to when they use the figure numbers. When they give you a diagram, it's a sketch. It's not a photo. It's just a rough, black and white sketch and a lot of the times they're out of proportion. It's hard to tell what piece of equipment they're talking about.

"This [the IETM] is done with a 3-D scanner, it's 100 percent in the dimensions, so right from the bat it's easier to tell what piece of equipment we're talking about.

"The 3-D image view is a godsend because you can pull it apart and find out down to the last screws what item they're talking about and it links it right to the description of that IETM."

While some people are "set in their ways," reluctant to accept the manual, the users love the IETM, says Kallopoulos. The computer access and technology accessible on CROWS and the Spider System also make both systems a suitable platform for IETM.

"The users motivated us," said Kallopoulos. "We train them to read through the instructions before performing them and no one likes to really do that because we're spending 15 or 20 minutes reading about a procedure that you don't understand until you get on the system.

"[With the IETM], they are actually seeing it performed and it helps them out drastically. We strive to give [the users] the best product that we can on the field so that it reduces the time it takes to repair the systems out in the field."

The 3-D interactive manuals, which started in late 2011, are expected to be fielded within the next three months.

---

The Armament Research, Development and Engineering Center is part of the U.S. Army Research, Development and Engineering Command, which has the mission to develop technology and engineering solutions for America's Soldiers.

The research center, also known as ARDEC, is the largest organization at Picatinny Arsenal, which is a major employer in northern New Jersey. The center has acquired a reputation for quality improvement and plays a vital role in developing superior armament technology for the U.S. Army and other branches of the nation's military.

ARDEC is one of the largest employers in northern New Jersey, employing 3,378 people on site here, with an additional 377 at other locations. More than 2,481 ARDEC employees are scientists or engineers.

By designation of the Secretary of Defense and an act of Congress, Picatinny Arsenal is the Department of Defense's Joint Center of Excellence for Armaments and Munitions. Picatinny's portfolio comprises nearly 90 percent of the Army's lethality and all conventional ammunition for joint warfighters.

A 6,500-acre military installation located in Morris County, the Arsenal contributes more than $1.3 billion to New Jersey's economy.

Related Links:

U.S. Army Armament Research, Development and Engineering Center (ARDEC) homepage

U.S. Army Research, Development and Engineering Command (RDECOM) homepage

Social Sharing