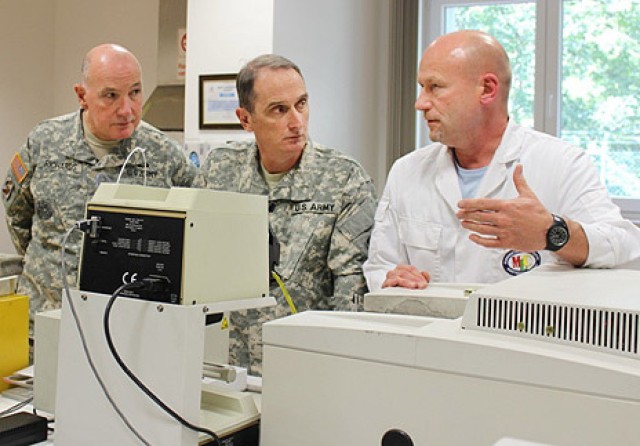

KAISERSLAUTERN, Germany -- U.S. Army Europe Command Sgt. Maj. David Davenport visited the 405th Army Field Support Brigade's Army Oil Analysis Program laboratory here Aug. 12.

The AOAP is a Department of Defense program to detect impending equipment component failures and determine lubricant condition through on-line and laboratory evaluation of oil samples.

The Army Oil Analysis Program Laboratory-Europe provides commanders in Europe, Africa and Southwest Asia with oil analysis capabilities at the Kaiserslautern Army Depot. The lab's primary mission is to accept oil samples from both aircraft and ground-based vehicles and analyze them for flaws and inconsistencies. After receipt of the samples, the lab must analyze and report back to aviation units within 24 hours, and ground units within 72 hours.

"I am amazed at the amount of work and scientific expertise that goes into ensuring flight safety, equipment readiness and the work ethic of the employees at the laboratory," Davenport said.

Davenport was joined on the visit by Command Sgt. Maj. Stanley Richards, 405th AFSB's new senior noncommissioned officer.

It is a relatively quick process to sample lubricants with the labs array of equipment. Doing so can save hours of maintenance downtime through early detection of such problems as faulty air-induction systems, leaking cooling systems, loose crossover lubricant lines, and abnormal wear rates of moving metal parts.

"The AOAP lab offers units an opportunity to have their equipment's oil and other fluids tested with some of the most technologically advanced tools available, thus enhancing the ability to make sound, proactive and cost effective maintenance decisions," Richards said. "I do not know why anyone would not take advantage of this capability."

Heidi Bodeit, laboratory director, and her team walked Davenport and Richards through the process of extracting the oil sample, inspecting by microscope and photographing and electrically testing for impurities.

"I was amazed at the quick and efficient way of testing samples and keeping our force ready," Davenport said.

At the end of the tour, Davenport presented a "Commander's Coin of Excellence" to Bodeit and "For Warrior Excellence" coins to Dahab Gebreyohannes and Detlef Nuss, both physical science technicians, for their work at the organization. Akwasi Edusei, administrative support specialist, also received a "For Warrior Excellence" coin.

Related Links:

Army Sustainment Command homepage

Army Sustainment Command Facebook page

Social Sharing