Adam Smith, a civil engineer from the Southwest Division Dam Production Safety Center at the Tulsa District, said he first began using 3D modeling software about five years ago, while assigned to the Military Design section, which is plans infrastructure projects for military installations within the district.

When Smith moved into Civil Works, he took his knowledge of the modeling software with him and began applying it to Civil Works projects.

"The first project we thought it would be useful on in Civil Works was a hydraulic structure package at Canton Dam," said Smith. "It was principally a structural design with a civil works discipline support role. We felt because the size and sensitivity of project costs that using 3D could benefit cost and reduce potential long-term costs. We noticed an improvement in the accuracy of quantities, which better supported the cost estimate and reduced the risk of incorrect cost estimates."

After the success at Canton, the benefits of 3D modeling software began to shine through. He continued to improve his knowledge of the software and build upon it with each succeeding project. When he moved to the Dam Safety Production Center two years ago, where much of his section's mission involves rehabilitating existing dam and levee structures and the construction of new structures, he took that knowledge with him.

"With each project's success with modeling we've continued to use it on more and more projects. With the Keystone Bridge construction we have had a lot of success because a lot of the components were precast," said Smith

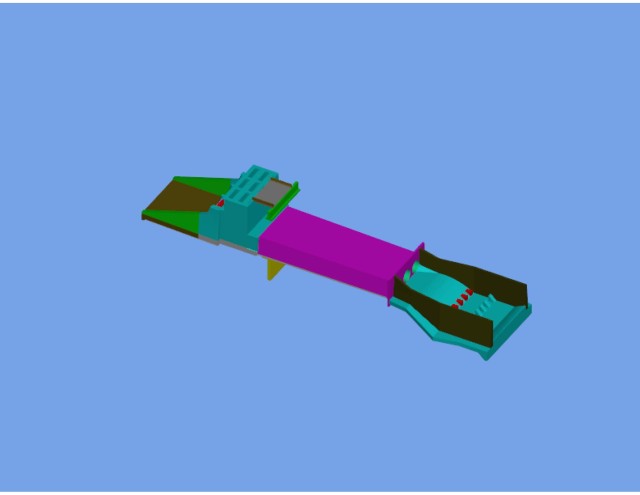

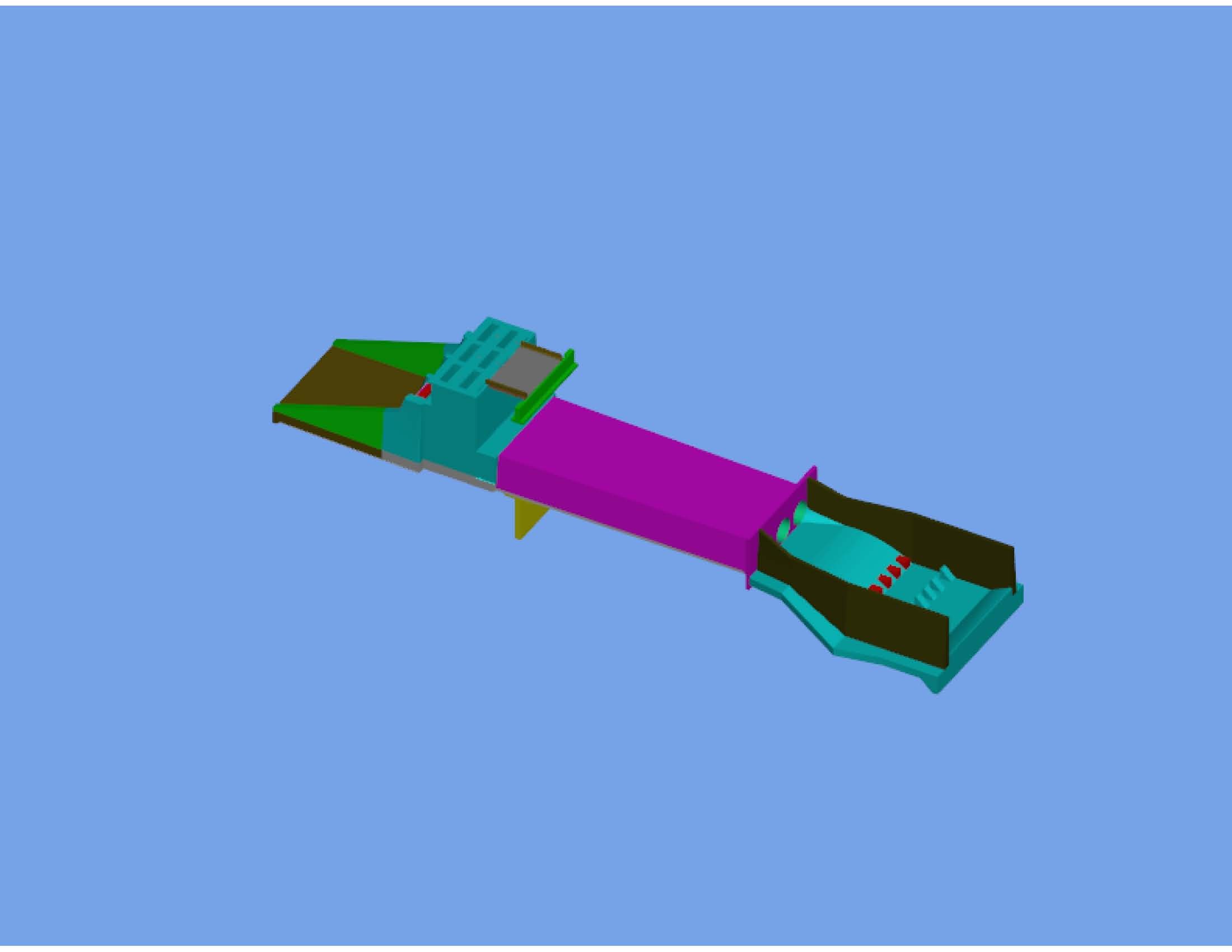

Currently Smith is working with a team of engineers from the Little Rock and Galveston Districts to plan and design the site for a new outlet work at Addicks and Barker Dam outside of Houston, Texas. Outlets will control the amount of water flowing from the upstream reservoir. The current outlet work will be abandoned in place and grouted down.

Mark McMahon, the lead structural engineer on the Addicks and Barker Dam project, from the Little Rock District Dam Safety Production Center said the software has shown many benefits.

"It's fantastic for figuring out quantities of concrete," said McMahon. "Within seconds of the model being complete, you are able to determine the volumes."

The 3D models also allow for improved communication geographically separated individuals.

"Most of our meetings are virtual," said McMahon. "Whenever we have meetings we can pull the 3D model up during a webinar and everyone can see it. It just makes it easier."

Because the software provides a dynamic visual representation of the site planning, it has the potential for savings on travel.

"Before the 3D models, we had to meet in the same physical location. I'd have to be TDY [temporary duty] to Galveston for maybe a month or two, and that's the same with the other engineers on the project," said McMahon.

The software also enables the Corps of Engineers to provide contractors with a more accurate depiction of the work that needs to be performed. The three dimensional representation will depict objects as small as three-eighths of an inch, and because the models can be quality-checked in real-time, corrections can be made quickly which helps prevent potential conflicts.

"Because we have a model, we know exactly where the slope of a wall ends and allows us to develop sectors for drawing and better depict the intent of design for the contractor," said Smith. "If an outside slope doesn't match-up, it will force the contractor to make in-field changes that maybe an engineer wouldn't be aware of."

Social Sharing