TOBYHANNA ARMY DEPOT, Pa. -- After a rigorous four-day inspection of Tobyhanna's processes and business practices, the depot was awarded recertification for meeting and exceeding recognized quality standards.

Auditors from NSF International visited the depot last month to conduct a reassessment audit of Tobyhanna's Aerospace Standard (AS) 9100, AS9110 and International Organization for Standardization (ISO) 9001 certifications.

The auditors used a 'plan-do-check-act' method to look at various aspects of product and process quality throughout the mission, and to ensure the depot continues to provide the warfighter with the highest quality product possible. Key aspects evaluated include customer focus, monitoring and measuring of products, configuration management, preservation of product, identification and traceability, risk management and continuous improvement.

Lead auditor Merlyn O'Hara said Tobyhanna has made tremendous strides over the last year in order to improve processes, but has some room for improvement.

"It's clear that Tobyhanna has matured its systems and processes and has made vast improvements since the last audit," said O'Hara. "All of the faults we found were minor in nature and rely on sustainment to allow for continued support."

Sustainment, O'Hara noted, is the depot's main focus when preparing for the audit and is also the driving force behind achieving AS and ISO quality standards. Cletus Campbell, quality assurance specialist in the depot's Productivity Improvement and Innovation Directorate, echoed the auditors' stress on the importance of sustainment.

"One reason we conduct internal audits is so that we can continually meet and exceed quality goals and sustain our reputation as an industry leader," said Campbell. "But we can't look at this audit as something that is over and done with until next year. We need to continue doing the same things we did to prepare for the audit."

Auditors also attributed the depot's quality excellence to the all-hands-on-deck effort of Quality Star Points, who take preventive action to identify potential and recurring problems.

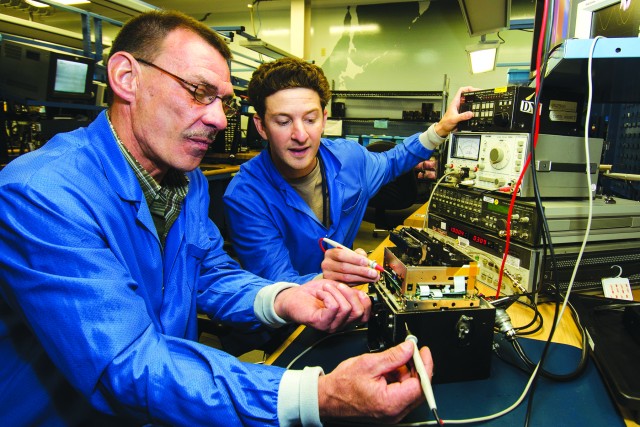

One of the mission areas placed under the microscope during the audit was the Command, Control and Computers/Avionics Directorate's Flight Control Systems Branch. The branch overhauls, repairs, modifies and tests several high frequency radios and other aircraft components according to aerospace standards, and was thoroughly examined throughout the audit.

Branch Chief John Stochla said he stresses constant preparedness and encourages branch employees to fully-use resources and communication channels to continue meeting quality standards.

"Our goal is to always be audit ready," he said, highlighting the importance of adhering to sustainment benchmarks to avoid having to scramble last-minute. "It's good to hear that we're doing well [meeting quality standards] from an external source, but we don't ever want to have to make a mad dash to the finish," Stochla added.

Allen Kresge and Frank Gervasi, electronics mechanics in the branch, said Stochla's mantra was apparent to the auditors and is key to readiness.

"The auditors said we were well-prepared, which is something we practice and harp on every day," said Kresge.

"John tells us to 'say what we do and do what we say,' and to focus on communication," noted Gervasi.

O'Hara and the other NSF International auditors recognized the knowledge, skill and management commitment of the depot work force, something Campbell said helps Tobyhanna serve its most important customer.

"It's not about simply following a rule or meeting a standard," said Campbell. "Our goal is to improve the quality of our processes, products and our business to better serve the warfighter."

Depot commander Col. Gerhard P.R. Schröter added that the audit is essential for depot growth and continued support of the warfighter.

"This was a team effort and everyone on this depot did their part to ensure we continue to hold this significant national recognition. The ISO/AS certifications are critical to our ability to attract new workload and keep our current customers coming back."

Certification is valid for three years, with an initial assessment taking place the first year and surveillance audits the second and third years of each cycle.

Tobyhanna Army Depot is a recognized leader in providing world-class logistics support for Command, Control, Communications, Computers, Intelligence, Surveillance and Reconnaissance (C4ISR) Systems across the Department of Defense. Tobyhanna's Corporate Philosophy, dedicated work force and electronics expertise ensure the depot is the Joint C4ISR provider of choice for all branches of the Armed Forces and industry partners.

Tobyhanna's unparalleled capabilities include full-spectrum support for sustainment, overhaul and repair, fabrication and manufacturing, engineering design and development, systems integration, technology insertion, modification, and global field support to warfighters.

About 3,500 personnel are employed at Tobyhanna, which is located in the Pocono Mountains of northeastern Pennsylvania. Tobyhanna Army Depot is part of the U.S. Army Communications-Electronics Command. Headquartered at Aberdeen Proving Ground, Md., the command's mission is to research, develop, acquire, field and sustain communications, command, control computer, intelligence, electronic warfare and sensors capabilities for the Armed Forces.

Social Sharing