Modern Weapon Design (EM486B) is a 12-week elective course offered every spring to seniors (and sometimes juniors in advanced studies), and is taught by Naval Surface Warfare Center Indian Head Explosive Ordnance Disposal Technology Division (NSWC IHEODTD) Senior Intelligence Officer Ken Conley.

Rubbing their hands together briskly Tim Walters and Matt Riloff very cautiously and carefully placed their improvised explosive device on the make-shift stand, aiming it directly at the thick steel plate ahead of them. Once placed, the men crouch on the cold, muddy field, checking alignment once more, and hoping they've placed the charge where it will inflict the most damage to the structure. Then they stand, and walk eagerly down the hill to the small hut where they can witness their engineering masterpiece in action.

MIDN 1/C Walters and MIDN 1/C Riloff are two of eleven midshipmen, or "Mids," who spent the semester learning about modern weapon design and metal material characteristics in an energetics-based course taught at the U.S. Naval Academy in Annapolis, Md., Jan. 7 - April 29.

Modern Weapon Design (EM486B) is a 12-week elective course offered every spring to seniors (and sometimes juniors in advanced studies), and is taught by Naval Surface Warfare Center Indian Head Explosive Ordnance Disposal Technology Division (NSWC IHEODTD) Senior Intelligence Officer Ken Conley.

"I began teaching the course while on active duty as an engineering duty officer," said Conley. "When I transitioned to civil service, the academy staff asked me to continue teaching the elective course, and IHEODTD leadership was very supportive. Any engineering student can sign up for the course, but it's really more geared toward those students studying mechanical engineering."

According to Conley, the course covers theory, practical knowledge exercises, two days in the machine shop (where students fabricate and modify their designs), a warhead design exercise, and one day in the field where they get to put their creations to the test. Conley also brings in other ordnance experts from NSWC IHEODTD as guest lecturers who bring in designs for the students to explore. Physicist Carl Gotzmer taught the students about Reactive Materials. Dr. Al Stern taught explosive and propellant ingredient development and properties. Dr. Dan Pine discussed research on initiators and microelectromechanical systems (MEMS). Engineers Tim Hennessey and Annmarie Shahan covered a section on warheads, and Brian Shaffer taught a section on Explosively Formed Projectiles.

"In addition to what they learn about the metal characteristics and properties, such as ductility and tensile strength, the course is also a great opportunity to introduce our future Navy leaders to the Navy labs and Warfare Center Divisions," continued Conley. "Most of these young men and women are going off to the Fleet, and it's good for them to have exposure to, and an understanding of, where many of the Navy's future capabilities come from."

For the hands-on parts of the course, the Mids first use the Academy's machine shop to design, machine, and modify their own explosively formed projectile (EFP) designs; and then travel to the U.S. Army's Blossom Point Research Facility, near Welcome, Md., to detonate them on one of the facility's test ranges.

"In the shop, the students fit a small circular and curved pressed metal disc inside of a PVC pipe. Once they finish with their design and modifications, we take their devices out to Blossom Point where our technicians loaded in C4, added a detonator, and helped the students properly aim their IED at a steel-plate target," said Conley. "We supervise the students in the shop and on the range to ensure everyone's safety and provide assistance. Because of our energetics and EOD experience, we have a pretty good idea about what type of designs will work best. However, when the students design and manufacture their devices, we don't intervene. One, we want them to try out new stuff, not just what's already been done. Also, because of our experience, it would be easy for us to get wrapped around what's supposed to be done. By not limiting them, we often find the students will come up with a unique design, something we haven't seen or tested before - which means we get to explore something new, too."

So, how did Walters and Riloff's project fare?

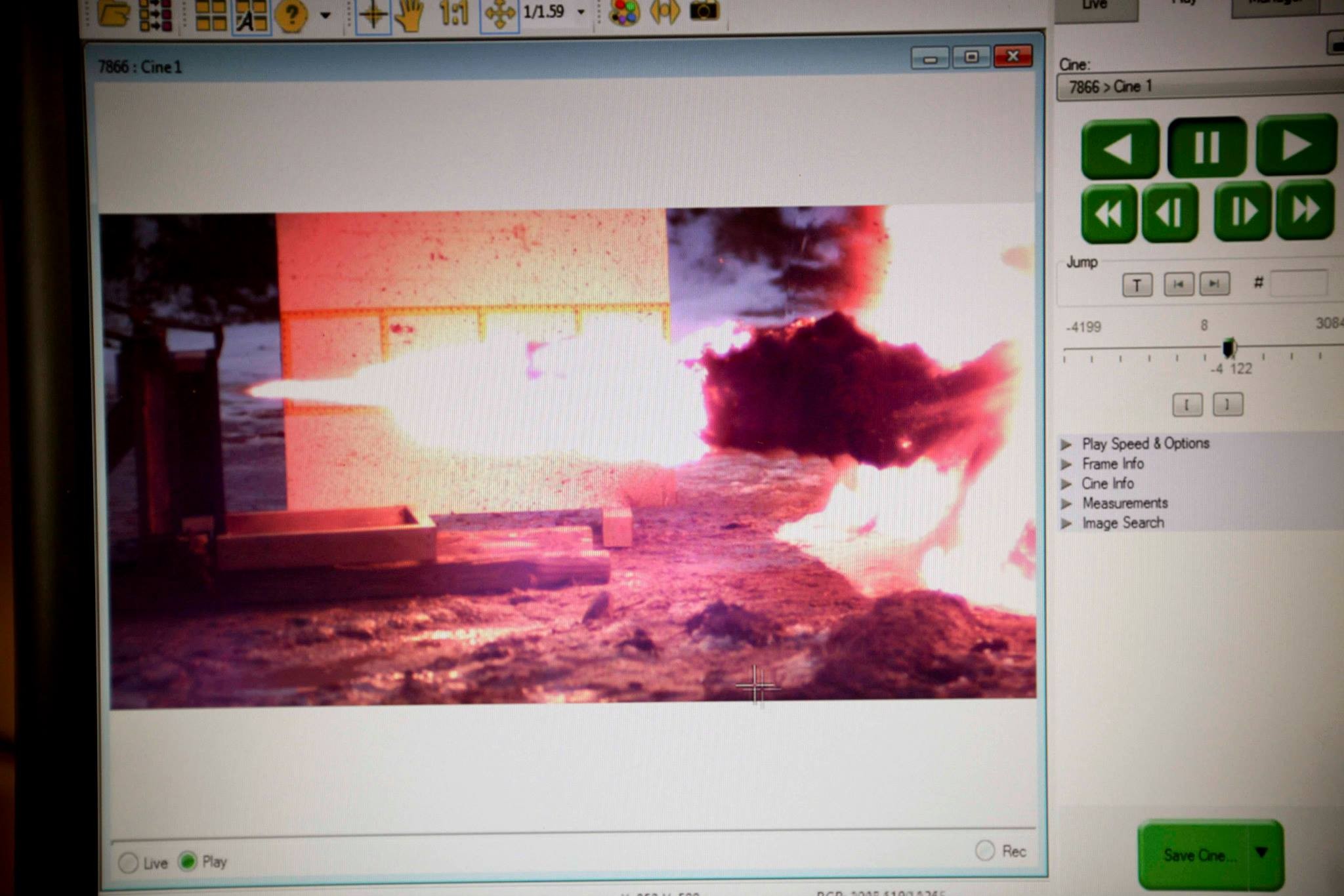

Back in the hut behind the safety berm at Blossom Point, the two young men stare at the large monitor shoulder-to-shoulder with fellow Mids - excited to see the results of their effort and hoping to make a good showing among the other designs. NSWC IHEODTD engineers and technicians remotely detonate the device and document the event with high-speed video from the small building's control station.

Within seconds the small building exploded with hoots and yells as the students watched the team's fiery ball pummel the steel plate in front of it. Cheers come again as the results are played back for the group in slow-motion.

After the range is cleared and deemed safe, the class is led back onto the test site to examine the damage produced and to help ready the next team's device.

Trudging back up the hill through the mud, Walters and Riloff triumphantly retrieve the steel plate from the ground, excited to show everyone that they can now peer through the two-inch steel plate from the centrally-placed hole.

"This is hands-down the best school day ever," said Walters. "Our design had a longer PVC pipe barrel, it was about the same size as a traditional EFP, but it had a bit more pipe extended at the front. In the end, our design worked out really well."

Of course, most engineering breakthroughs are built on previous failures, and while not all of the designs ended up piercing steel, everyone learned valuable lessons from the experience.

"Like any true engineering effort, students learn as much, if not more, from the designs that don't work," said Conley. "From there, we have an opportunity to discuss what didn't work, to figure out why it didn't work, and how to change our design until we succeed."

"We wanted to try something different and see what would happen. So, we tried some really thick brass without any additional material. In the end, it had an interesting shotgun effect, but broke apart too soon. We also learned that brass isn't a good material for this use because it's an alloy. If we got to do it again, we would definitely go with a thinner material, probably copper," said MIDN 1/C Parker Pierson. "This course has been a great overview of military weapons, what they do, and how the engineers design them. This would be a really interesting field to go into after I leave the military, and I like the thought of going on to support the Warfare community, as well."

NSWC IHEODTD - a field activity of the Naval Sea Systems Command and part of the Navy's Science and Engineering Enterprise - is the leader in ordnance, energetics, and Explosive Ordnance Disposal (EOD) solutions. As a Department of Defense Center of Excellence and EOD Detection Equipment Program lead, NSWC IHEODTD focuses on energetics research, development, testing, evaluation, in-service support, and disposal; and provides warfighters solutions to detect, locate, access, identify, render safe, recover, exploit, and dispose of explosive ordnance threats.

As the undergraduate college of our country's naval service, the U.S. Naval Academy prepares young men and women to become professional officers of competence, character, and compassion in the U.S. Navy and Marine Corps. Naval Academy students are midshipmen on active duty in the U.S. Navy. They attend the Academy for four years, graduating with Bachelor of Science degrees and then commissioning as Ensigns in the Navy or Second Lieutenants in the Marine Corps. Naval Academy graduates serve at least five years in the Navy or Marine Corps.

Blossom Point Research Facility is a 1600-acre U.S. Army site located 50 miles south of Washington, D.C., in Charles County, Md., with multifunctional test ranges supporting an average of 125 programs a year. Customers include Navy Research Laboratory, Consumer Product Safety Commission, Defense Threat Reduction Agency, Naval Surface Warfare Center, Army Research Laboratory, and U.S. Special Operations Command.

Social Sharing