As logisticians, we first must match requirements with capabilities in order to define and extend the possible. Next, we must design creative contingencies that are easily integrated with the operations of those we support. Last, we must be innovative, agile, and adaptive to keep pace with the tactical operations conducted by our maneuver counterparts.

Typically, Joint Readiness Training Center (JRTC) rotations at Fort Polk, La., cater to the brigade combat team (BCT). In the case of E Company, the forward support company (FSC) for the 7th Battalion, 101st Aviation Regiment (7-101st General Support Aviation Battalion [GSAB]), 159th Combat Aviation Brigade, the rotation was unique. JRTC Rotation 13-10 catered to the 7-101st GSAB, a multifunctional aviation task force. A ground force did not deploy to JRTC, which meant that the FSC would have no reach-back support.

The intent was clear: E Company had to extend the maneuver battalion's operational reach by providing class I (subsistence), class IIIB (bulk petroleum, oils, and lubricants), and class IX (repair parts). The task force commander's intent was to validate his capabilities in support of the ground force commander's requirements.

In the absence of higher echelon support, E Company had to fill the logistics requirements that are normally covered by the aviation support battalion (ASB) and, in many situations, a brigade support battalion (BSB) organic to a supported BCT. To set the conditions, the company assumed tasks of the ASB support operations section while executing deliberate command post operations that enabled the FSC commander to intuitively implement mission command at all levels.

With that in mind, E Company implemented the fix-fuel-feed concept as one of the company commander's priorities to ensure a successful rotation. Additionally, FSC leaders briefed a sustainment plan and conducted a sustainment rehearsal with the task force commander and staff to ensure all the key players understood how logistics would be integrated during each phase of the operation.

The company commander's fix-fuel-feed priorities were as follows:

• Fix: Maintain the task force ground equipment at a 90-percent operational readiness rate.

• Fuel: Properly track fuel consumption to mitigate the possibility of aircraft being grounded. "Keep'em flying."

• Feed: Execute a seamless field feeding plan that is synchronized with the task force flight schedule.

FIX

E Company deployed to JRTC with three 92A (automated logistical specialist) Soldiers. Normally, the entire sustainment automation support management office from the BSB would deploy to help troubleshoot logistics information systems on the battlefield.

During the initial in-progress review for the JRTC rotation, it was noted that the FSC would have no reach-back support. This was an issue because the FSC was set to deploy to JRTC with only 69 Soldiers. The company requested that a sustainment automation support management office representative from the ASB be attached to the company for the rotation.

Within 24 hours of its arrival at the forward operating base, the company set up the very small aperture terminal. It began requisitioning parts from the supply support activity the following day. Establishing this critical information system enabled the maintenance control section to quickly input data for vehicles drawn from the pre-positioned stock yard.

Most aviation flight companies are not authorized executive officers, so the maintenance control sergeant, with the assistance of the FSC executive officer, managed the 026 report for the battalion to ensure parts were being ordered correctly through the Standard Army Maintenance System-Enhanced.

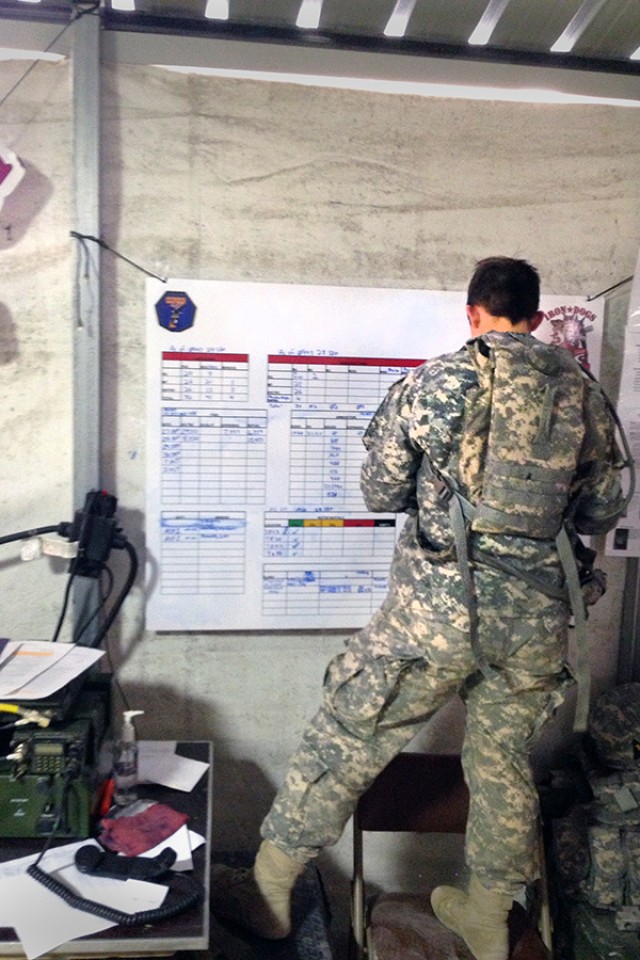

The FSC operations section created trackers and made updating them, at 0800 and 1700, daily battle rhythm events. This allowed any Soldier who entered the command post to know what equipment was not mission capable and what parts were on order to make it fully mission capable.

FUEL

Logistics support is essential for continuous operations at JRTC. It must be delivered seamlessly by forecasting operational needs and coordinating with supplying units. Class IIIB was essential in these continuing operations, particularly to the aviation task force.

The distribution platoon deployed with six M978 heavy expanded-mobility tactical trucks (HEMTTs), two advanced aviation forward area refueling systems, and other distribution equipment for the heavy use of fuel forecasted to support the rotation.

At JRTC, class IIIB was drawn directly from Cubic-ESG [exercise support group]--a contractor that typically works and communicates with the BSB support operations office--and transferred directly to the distribution platoon for refueling operations. In this method, known as throughput distribution, at least one echelon in the supply system is bypassed to minimize handling and speed delivery.

Although this may sound simple, it places additional duties on the receiving unit's distribution platoon. The FSC operations section must request fuel through the battalion S-4 and, in most cases, coordinate with Cubic-ESG because of the ever-changing environment.

The mission of the distribution platoon at JRTC was to ensure all aircraft were topped off with aviation fuel throughout the exercise in order to continue operations. However, the implied task was to accurately forecast fuel needs because it was essential to have the right amount of fuel on hand without fail and to forecast a fuel drawdown so that there was no excess fuel at the end of the rotation.

To accurately determine fuel numbers, several factors need to be examined in relation to each other: total fuel storage capacity of the distribution platoon (such as HEMTT fuel tankers and fuel blivets), the number of aircraft being fueled throughout the rotation by type (including their fuel capacities and consumption rates), flight schedules and anticipated movement, and the possible times to receive fuel pushes from Cubic-ESG.

Until efforts to draw down begin, having a near-capacity supply of fuel going into nighttime operations is preferable. Proper forecasting allows units to continue operations until the end of the exercise and then distribute the remaining fuel by predetermined methods. The receiving unit's commander should regulate fuel resupply in order to approve its release for issue and avoid conflicting directives.

The modified table of organization and equipment did not authorize critical skill sets that the FSC needed when the aviation battalion was task-organized for JRTC. The mission the FSC received involved running two active forward arming and refueling points (FARPs) simultaneously and being ready to launch a jump FARP on order. This required 89B (ammunition specialist) and 15J (OH-58 armament/electrical/avionics systems repairer) Soldiers, who were requested from D Company and the ASB.

FEED

The FSC's assumption of ASB roles led to its very deliberate training to complete the tasks. One example is the implementation of a concept of support and a synchronization matrix to assist with the planning effort for situational training exercises and force-on-force exercises. At the beginning of the situational training exercises, the FSC developed the concept of support with the data of all classes of supply used by the troops over the first week of training.

The FSC used a throughput supply flow system because of its on-hand capabilities. Two large refrigerated containers were used to keep a three-day supply of unitized group rations-A on hand. Allocating class I rations was possible because of the direct relationship the FSC developed with the troop issue subsistence activity 100 days before arriving at JRTC.

Through a contract with Cubic-ESG, the FSC also had three bulk water supply points and four water buffaloes on hand to provide more than 3,000 gallons of water a day. The goal was for all 800 Soldiers to have two hot meals daily (plus a meal ready-to-eat, for lunch) and ensure uninterrupted field feeding at JRTC.

The JRTC rotation for E Company, 7-101st GSAB, posed a number of unusual challenges. It also provided an excellent opportunity for the FSC to learn from those challenges. The FSC staff identified the following lessons learned based on this JRTC rotation:

• Conduct precombat checks and inspections aggressively at the platoon level. Conduct daily synchronization meetings with the big 3 (commander, first sergeant, and executive officer).

• Reach out to the observer-coach/trainers at JRTC for trends, and communicate with them early and often before the rotation starts.

• Create trackers to facilitate a common operational picture and forecasting at the company level.

• Enable mission command by encouraging disciplined initiative.

• Look for opportunities to cross-train Soldiers to build depth and flexibility for the supported unit.

• Empower leaders to develop a relationship that builds trust and respect with the customer.

• Every mission should incorporate troop leading procedures.

• Ensure all filter separators are tested; fuel filter effectiveness tests should be done every 30 days according to regulation.

• Establish playbooks for FARP operations--silent FARP, jump FARP, and active FARP--and rehearse them before the combat training center rotation.

• Communication is key; no operation is successful without flat and continuous communication among adjacent commanders.

• Conduct teleconferences with Army Materiel Command personnel early and often to set the conditions for logistics support.

___________________________________________________________________________________________

Capt. Carlos M. "Mike" Sanford is the company commander of E Company, 7th Battalion, 101st Aviation Regiment, 159th Combat Aviation Brigade. He holds a bachelor's degree in history from Methodist University and a master's degree in logistics management from the Florida Institute of Technology. He is a graduate of the Transportation Officer Basic Course and the Combined Logistics Captains Career Course. He also was a 2012 Institute for Defense and Business Strategic Studies Fellow.

1st Lt. Ryan C. Cloud is the executive officer of E Company, 7th Battalion, 101st Aviation Regiment, 159th Combat Aviation Brigade. He holds a bachelor's degree in health care administration from St. Joseph's College of Maine and a master's degree in public health with a certificate in disaster management from Benedictine University. He is a graduate of the Quartermaster Basic Officer Leader Course, the Unit Movement Officer Course, and the Sling Load Inspectors Course.

1st Lt. Timothy D. Hryniewicz is the distribution platoon leader of E Company, 7th Battalion, 101st Aviation Regiment, 159th Combat Aviation Brigade. He holds a bachelor's degree in criminology from Central Connecticut State University. He is a graduate of the Officer Candidate School and the Ordnance Basic Officer Leader Course.

___________________________________________________________________________________________

This article was published in the May-June 2014 issue of Army Sustainment magazine.

Related Links:

Browse Army Sustainment Magazine

Social Sharing