The Retrograde, Reset, Redeployment, Redistribution and Disposal (R4D) mission in Afghanistan has a lot of moving parts. More than 750,000 major end items worth more than $36 billion are currently in Afghanistan, according to DOD estimates. This R4D effort is expected to cost some $5.7 billion and will require intricate planning, teamwork, creativity and innovation. The Army G-8 will be at the heart of it.

Army AL&T magazine wanted to understand the G-8's overarching role in R4D better. We sat down on July 25 with Mr. Donald Tison, assistant deputy chief of staff, G-8, and Col. Gregg Skibicki, chief, G-8 Force Development Operations and Integrations Division, to discuss the G-8 role in coordinating the reset aspect of the massive R4D effort.

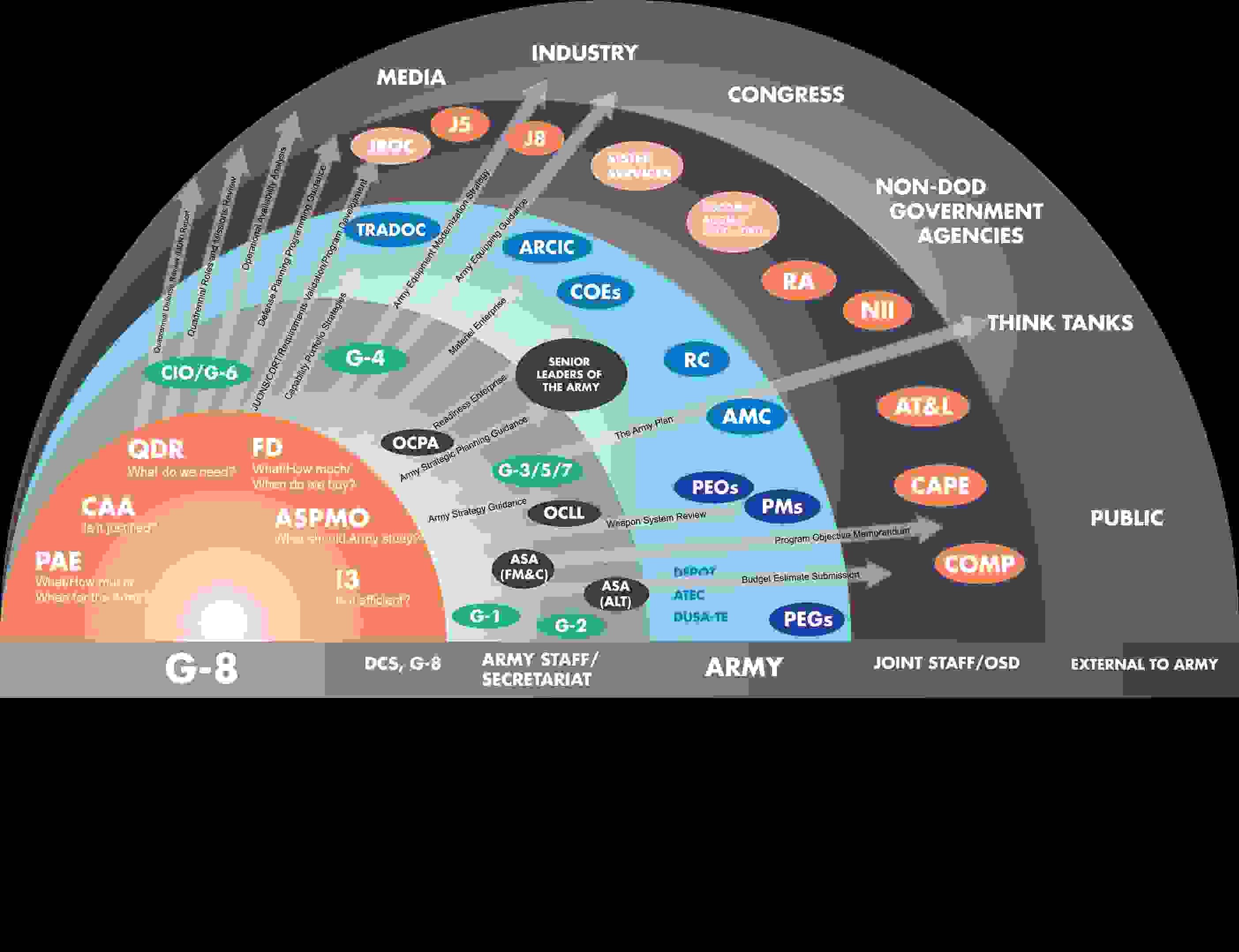

The Army G-8 is the service's lead for matching available resources to the defense strategy and the Army plan. G-8 accomplishes this through participation in defense reviews and assessments led by the Office of the Secretary of Defense; the programming of resources; materiel integration; analytical and modeling capabilities; and the management of DA studies and analyses. The G-8 team comprises one field operating agency, the Center for Army Analysis; three directorates--the Army Quadrennial Defense Review Office; Program Analysis and Evaluation; and Force Development--and the Army Study Program Management Office.

The team works to plan, develop and resource programs supporting Soldiers by balancing current force needs with future force capabilities. As part of this mission, the team equips the Army through a balanced investment program to provide Soldiers the equipment that they need to succeed in full-spectrum operations, now and in the future. G-8 does so by bringing to the table all the lines of effort to integrate and coordinate activities.

Army AL&T: We understand that the G-8 primarily focuses on the reset portion of R4D. What is the Army G-8's role?

Tison: G-8 synchronizes activities for the reset task force that looks at the requirements, the resources and the assets. We received our first $17 billion of reset funding in 2006 when Secretary of the Army Francis J. Harvey and Gen. Peter J. Schoomaker chief of staff of the Army were here. Maj. Gen. Stephen M. Speakes was the G-8 director of force development. The leadership decided the Army needed a centralized effort to coordinate the reset of Army equipment returning from overseas. Army leadership asked the G-8, since the predominance of the equipment was G-8-related, to put together what I will call a task force. It isn't really a task force in the conventional sense, but it's a task-organized team to plan, coordinate and provide oversight for reset operations.

With our integration role, we put together a group that has Army Materiel Command (AMC), G-4, the Office of the Assistant Secretary of the Army for Acquisition, Logistics and Technology (ASA(ALT)), the Army Budget Office (ABO) within the Assistant Secretary of the Army for Financial Management and Comptroller (ASA (FM&C)), G-8 and other organizations' subject-matter experts (i.e., lines of effort) to coordinate the programmatics in terms of the resources and the requirements to get it done.

We have worked reset through a variety of efforts since 2006, in both Iraq and Afghanistan. And, like anything, once you do it for a while, folks get comfortable with how it is done, so you move past the biases of organizations and folks come to the table to make reset decisions. We had a reset task force meeting yesterday and brought up a number of important issues not just about execution, but also how we are looking at fiscal year 2014 and the budgetary reductions on reset.

There's no permanent structure behind it. We call the lines of effort together, and they come to the meetings ready to discuss and work issues. So we quickly develop a briefing strategy--what should we brief, how should we brief it--and lay out how we are executing the funding.

ABO provides current funding status, what money was deferred for reset and what we are doing on procurement. AMC talks to the sustainment process. We go through each one of these areas monthly. Then, if we have any issues, we take action items to solve them. It is a classic way to do business. You task-organize around the problem and work it.

Army AL&T: Can you give us an example of a particular issue that you've worked?

Tison: Sure. We're looking at the helicopter sustainment program. We have a program called Special Technical Inspection and Repair--STIR. When helicopters come back from theater, we employ an enhanced, phased maintenance approach whereby we work to get them ready for the next cycle. It's predominantly (overseas contingency operations) OCO-funded. The conversation we're having now is that, once the war stops in 2014 and '15, what follows STIR? Do we go back to phased maintenance, based mainly on flying hours? Or do we perform enhanced maintenance, improvements or modernization to meet long-term sustainment objectives?

We've had a series of conversations about the follow-on for STIR, and we believe that's going to be the aircraft inspection maintenance and sustainment program. But if we don't decide quickly, there are issues. You get past '14, with all the helicopters back, and there's no enhanced sustainment-level program in place for '15. We may lose our window of opportunity if we don't fix them in 2014-15. When will the opportunity present itself to get our helicopters up to the highest standards? And where do we do it? Do we use Corpus Christi Army Depot, Texas, or do we give more work to the local directorates of logistics, which are now operated by AMC, versus the local installation? We're actively working on this issue, because I think we're going to lose an opportunity if we don't get a program in place over the next couple of months as we work the 2015 OCO budget and look at transition with the requirements. The G-4 is heavily involved, AMC, Army Aviation and Missile Life Cycle Management Command and, of course, ASA(ALT). They are critical for any enhancements.

Army AL&T: What are the biggest challenges that G-8 is facing with respect to R4D, and how are you dealing with them?

Skibicki: There are actually three different working groups that are dealing with Afghanistan and equipping, when equipment is arriving, leaving and retrograding. The reset task force was the first, because that was all during Iraq. We also stood up a task force called the EDR2B, the Equipment Deployment-Redeployment Review Board, based on lessons from Iraq. We tried to meter the equipment going into and out of Afghanistan, and built the Theater-Provided Equipment (TPE) sets in Afghanistan to minimize the traffic flow in and out. We just stood up the third one in spring of 2013--the R4D process. In R4D, we focus on how we integrate the retrograde and redeployment with our reset task force work. The biggest challenge we have with the R4D is making sure we get the right equipment home at the right time to get it back into the hands of the next deployers.

Army AL&T: How does automatic reset induction (ARI) work? What role do tools such as the Lead Materiel Integrator (LMI) Decision Support Tool (DST) and the redistribution property assistance team (RPAT) play?

Skibicki: In ARI, every year we review the list of equipment and have a big conference with AMC, the lead materiel integrator for the Army Forces Command (FORSCOM), which is the readiness enterprise, and then the Headquarters, Department of the Army staff. All of the life-cycle management commands (LCMCs) are there, and most of the program managers and program executive officers are there. We review what the readiness drivers are across the Army over time, and then look at pieces of equipment that have been impacted by wear and tear, prioritizing what needs to go into sustainment-level repair first, and in what quantities.

Tison: Or what equipment [regularly] comes back and needs to be fixed. [For example,] generators--a generator goes over, and you know it's being used, and you know it's going to be automatically inducted to get maintenance. We review the status every year, because we found that some of the generators were going over and were never taken out of the box, so there was no need to bring them back through the depot to a reset line.

Skibicki: As we're looking at the equipment coming out of theater, we actually have three different paths of equipment return. First, we review the equipment in the ARI program to make sure we have the right equipment that must go to the depots for reset based on the extended wear and tear due to desert conditions; the overall operational readiness impacts of the equipment over time, the amount of stress on the equipment; and the overall readiness in the force. Predominantly, everyone thinks of tactical wheeled vehicles first. They are the biggest pieces of equipment going into the depots for reset. But, we also have a lot of communications equipment--radars and such--that are in the ARI program. Second, we have TPE that is returning to units, and those units are allowed to bring that set of equipment home. That equipment is field-level reset versus a sustainment (depot-level) program. We want to get most of the equipment out of theater that is not being used, when a unit is not backfilled or when equipment becomes excess based on changed mission requirements. We are transferring that equipment onto unit property books so the units can bring it back to home station for proper redistribution.

Tison: The beauty of the LMI approach is that as a unit brings equipment back onto their property books, the Army can get it into the correct unit through redistribution using the LMI DST. The LMIs, as they look at the equipment after it has been through the field-level reset, can redistribute it directly to units with the most need or to the next deployers, based on DST. We have seen that most of this equipment may be able to be used at a specific installation. Alternately, it may be redistributed within that geographical region. The unit can then act as the vehicle to bring it back from the area of operations.

Skibicki: The third way for the equipment to flow back is through the RPAT process and then be redistributed after sustainment-level reset. If the equipment is non-standard, it goes to the original equipment manufacturer for repair. Again, the LMI DST will redistribute the equipment based on the needs of the force.

Army AL&T: How does the Army balance the need for next-generation capabilities with the disposition of older materiel when resources for both are limited?

Tison: It's typically less expensive to fix something than to buy something new. What we were able to do with reset and recapitalization--and you can use your fighting vehicles or your tanks as an example--was to bring them back and upgrade them. As the Abrams came back, they came out as a System Enhancement Program or an Abrams Integrated Management tank. Bradleys came out as ODS [Operation Desert Storm] models or upgraded A3 models [with embedded diagnostics and integrated combat command-and-control digital communications suite]. We almost built them new. But you need a procurement office for that, so we worked closely with ASA(ALT) on the reset. That's important because, at least from an equipping perspective, your equipment is reset or recapitalized to the original or higher modernization level.

We also discuss the modernization issue, because equipment will age gracefully year after year, and so what is the future role? What's the role for Ground Combat Vehicle? For Joint Light Tactical Vehicle [JLTV]? For Kiowa follow-on? Do you continue to reset, recapitalize, or do you upgrade? Or do you have to go to a new system? That is the trade-off, and that's why you want the G-8 Force Development staff involved with the equipping portfolio and with ASA(ALT), because we can see the differences between classic equipping and modernization.

For JLTV, Mine Resistant Ambush Protected vehicles (MRAPs) proved very valuable in Afghanistan and Iraq, but would they be of value in other geographical areas? Or do we need something lighter and more flexible? And do we encounter technological issues because there is a protection/weight conversation? How do you get the right balance? But we really do need something to follow on the HMMWVs [High-Mobility Multipurpose Wheeled Vehicles], and so that's why JLTV seemed very practical.

Army AL&T: Virtually everything coming out of Afghanistan is going to need to be reset. Are there particular capabilities that are going to receive a higher priority?

Skibicki: Yes, there are. We took this on in G-8. Force Development introduced an initiative to develop a prioritized list of equipment for retrograde, reset and redistribution. It was actually three separate lists. The idea was to make sure that we did it in accordance with the equipment that was most needed for readiness and for the next deployers. The conversation starts with FORSCOM, the force provider and readiness enterprise. FORSCOM tells us what their priorities are for equipping the next deployers and building readiness across the force. We look at the most-needed capabilities across the Army based on shortages of equipment. Then, we look at what equipment we need to reach our aim points to get to the Army Force Generation [ARFORGEN] gates of the units being ready at a certain time, being available at a certain time, and what equipment is needed to make those units deployable.

We took that list, and then we went back and prioritized the equipment needed based on requirements, and worked with AMC and the LCMCs to determine what they could reset in that time period. For example, when we looked at tactical wheeled vehicles, we developed a prioritized list of light, medium and heavy tactical wheeled vehicles. We did a similar prioritized list for our combat vehicle priorities, as well as across our other assets (engineer equipment, artillery/air-defense artillery, aviation, weapons/night vision devices, communications, force protection, logistics and medical). In addition to developing priorities within each of those assets, there was also an overall prioritized list for the Army's retrograde, reset and redistribution. We did it for rolling stock, non-rolling stock, and now we're doing it for non-standard equipment. As we bring that equipment back, there are some pieces of non-standard equipment, such as MRAPs, for which the depots are conducting reset. We prioritize according to what we believe the needs are, and we vet it with G-3 for the requirements.

And G-3 then publishes the list that says, "Here's what the Army is going to retrograde out of theater, what we need to reset, and what we're prioritizing for redistribution across the force to meet the needs of the next deployers, fill our readiness needs and support the ARFORGEN gates." But the timeline is implemented in reverse. Redistribution is the equipment we need in the next 6 to 18 months, and that equipment is in reset right now. Our priorities for reset in the next fiscal year are the equipment needed in the next 24 to 36 months. And, finally, what's prioritized for retrograde is needed out to 48 months, or sometimes even further out because of delays in the programs [due to sequestration or continuing resolutions].

Tison: To give you an idea of what we do: The Army needs to have the resources to redistribute, reset and retrograde. On a monthly basis, we track operational work and all the procurement for AMC, for the depot maintenance, for all the field-level materiel--whether it is Army prepositioned-equipment sets, aviation STIR, the organizational clothing and individual equipment--we track what's happening, what's changed, what sequestration has done, to work through the process where we are now.

We turn next to ABO and look at how we are executing against it [the budget]. How is AMC doing? FORSCOM? TRADOC? What do we need to shift? This is what the reset task force is trying to bring together. We then go to talk to ASA(ALT) and say, "How are you spending the money? What's not been spent?" We do this each year. We try to synchronize requirements and resources with acquisition. It's relatively granular.

We also use the outcomes of this work to tee up conversations with the Hill. We frequently need to have dialogues with the House and Senate Armed Services Committees. A couple of years ago, we had too much money because there was a lot of equipment we thought we had to bring back to the States but instead were able to divert from Iraq to Afghanistan. We thought we'd have a heavier track requirement than we did, so there was a lot of work programmed for track maintenance, which wasn't needed. The result was that we had about $1 billion left over. So, we went over to the Hill and talked to professional staff members and made sure they knew what we were doing and why. Our task force work helped to shape that conversation.

Army AL&T: Can you tell us what the most important lessons learned are from retrograde in Iraq?

Skibicki: I think the number one lesson we learned was to bring everybody, all the lines of effort, to the table. We did that prior to the drawdown from Iraq with rehearsal-of-concept drills run by U.S. Army Central/Third Army (ARCENT) and AMC. ARCENT made sure that all the necessary participants were there, from the actual units that had the equipment and their higher-level commands, to the transporters, to the LCMCs that reset the equipment, the people developing requirements for diverting equipment from Iraq to Afghanistan, and ASA(ALT)--everybody was there. We made sure all of the subject-matter experts and members of the team were involved. The last session we had of the R4D General Officer Steering Committee, we made sure everybody was there--Army National Guard, U.S. Army Reserve, FORSCOM--all the affected commands, because everybody has a different perspective. U.S. Army Pacific Command has a different perspective on what they need their units to bring back from Afghanistan, or what was previously left in theater by one of their units that still hasn't been returned or repaid.

Tison: We worked to get numbers on cost savings. We worked very closely with the Defense Logistics Agency, our deputy assistant secretary of the Army for cost and economics within ASA(FM&C), our costing folks. It just makes sense, particularly with the non-standard equipment. We're not going to maintain it anyway. It would cost more to ship back, and even in the case of foreign military sales, you still have to get it out of the country. You may remember the Equipment Distribution Review Board, where we were working very closely with the U.S. Department of State on foreign military sales. It's more challenging with Afghanistan because we don't have Kuwait next door; we can't drive the equipment and vehicles out as simply from Afghanistan as we could from Iraq.

It really is a village. We get all the various parties together and really try to keep the process synchronized with all of the various organizations. We do a lot of integration work in G-8, and the R4D process is very natural for us.

Skibicki: We are tracking every single unit--when they are coming out, when we have to build the Transportation Control Numbers for their movement--and are trying to automate so we can build the requirement for the transportation earlier. "Left of the RPAT yard" is what we're calling it now: Even before they move from their forward operating base (FOB) to turn in their equipment, we've already prioritized their equipment to return home, based on what was programmed into ARI, or what the unit has programmed into Automated Reset Management Tool for their field-level reset when they get back. We execute DST runs to determine what equipment units can bring home to fill shortages within the unit or redeploy for another unit on the same installation back in the States. We are simply trying to get equipment out of country as quickly and in the most efficient way possible, while trying to support the needs of the depots for reset, and building readiness needed for the next deployers.

Social Sharing