ABERDEEN PROVING GROUND, Md. -- With team members located in both Edgewood and Rock Island, the Edgewood Chemical Biological Center's Decontamination Engineering Branch, under Sustainment Engineering Division Chief John Kerch operates as one team revolutionizing Warfighter chemical and biological decontamination efforts.

"Our motto is one team two locations," said Jim Burns, an engineer within the Decontamination Engineering Branch. The Branch consists of five engineers working at ECBC Rock Island and eight engineers working out of Edgewood, MD. Together, the team has supported several Army organizations including TACOM-LCMC, Defense Logistics Agency, JPM-Protection and others.

The team has recently worked together to support three decontamination projects aimed at improving the effectiveness and supportability of current decontamination methods, saving money for the Army in the long run. These projects are the Mass Casualty Decontamination Limited Objective Experiment for the M26, the M100 Shelf Life Study, and updates to the M12A1 Super Tropical Bleach mixing procedures.

Mass Casualty Decontamination Limited Objective Experiment The Mass Casualty Decontamination Limited Objective Experiment (MCD LOE) is a project managed by the Joint Experimentation and Analysis Division (JEAD), a part of the Joint Requirements Office, in support of several organizations. The project is an experiment to evaluate several configurations, both Commercial off the Shelf (COTS) and Organic, and assess their relative ability to support MCD mission requirements, such as providing water to shower stations for ambulatory and non-ambulatory decontamination situations.

"Currently the Army uses commercial systems such as the Reeves Decontamination Equipment and TVI Decontamination equipment," said Joe Grodecki, a Rock Island engineer with the Decontamination Engineering Branch. "We are trying to do a couple of water tests to see if they could use an Army system such as the M26 small-scale decontamination apparatus instead."

Grodecki explained that using the M26 could be cheaper for the Army than their current systems, because the Army already owns M26 systems. These systems are also easily maintained since the users are already trained on the equipment and logistics support is already in place. Currently the group is in the initial phases of the evaluation.

ECBC is supporting the JEAD by managing the LOE, designing the experiment and leading the execution of the experiment. "Jim and I are working with Paul Tady, also from the Decontamination Engineering Branch to conduct testing to support a Cost/Benefit Analysis and feed valuable data to the community. Depending on the outcome, this project could be transitioned into a Program of Record," said Grodecki.

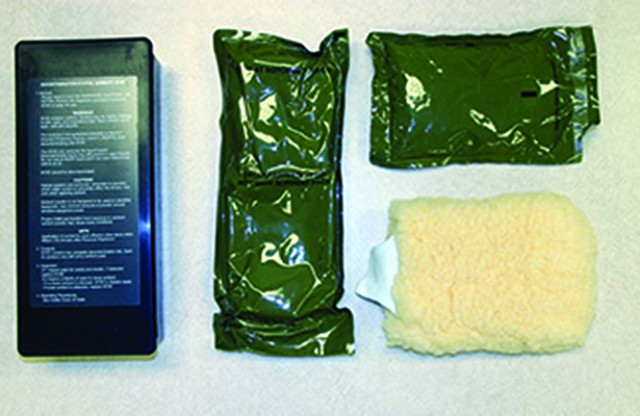

M100 Shelf Life Study

The M100 Shelf Life Study is an experiment to extend the shelf life of the M100 Sorbent Decontamination System. The M100 uses a sorbent powder for immediate decontamination, specifically, the removal of gross liquid contamination from frequently touched surfaces. Currently, the M100 has a shelf life of 10 years before it must be disposed of and replaced, but the Decon Engineering Branch is working to make that a bit longer.

"We've been working with TACOM to extend the M100 shelf life up to 15 years," Burns said. The team plans on testing select M100s every year from 10 to 15 years of life. "If we could continue to increase the shelf life of this product by 50 percent, it can save the Army a lot of money in the long run on replacement and shipping costs."

Supertropical Bleach

The use of Super Tropical Bleach (STB) has been a military decontamination method for decades. STB is a mixture of a several different chemicals and is used in several decontamination applications, to include decontamination of larger areas like vehicles and terrain. When applied using the M12A1 Decontamination Apparatus, STB is mixed into the hopper of the M12 Decontamination apparatus and disseminated using spray attachments. It was noted that the current mixing methods led to some issues such as foaming of the decontaminant, so the group sought to improve these methods. The team looked at a multitude of factors that influence the ease of STB mixing including water temperature and antifoaming agent.

"We were able to improve procedures within the M12 technical manual to help make the STB mixing process easier on the warfighter," Burns said. The results of the team's testing is being reflected in the M12 tech manuals, and a special message was also sent to users in the field providing interim guidance to smooth STB mixing operations.

Social Sharing